I-MAGNABEND - IZICABISO ZOKUQAPHA OKUYIMPHUMELA

I-Basic Magnet Design

Umshini we-Magnabend uklanywe njengozibuthe we-DC onamandla onomjikelezo womsebenzi olinganiselwe.

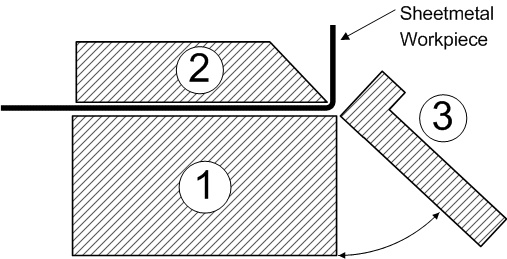

Umshini uqukethe izingxenye ezi-3 eziyisisekelo: -

Umzimba kazibuthe owakha isisekelo somshini futhi uqukethe ikhoyili kazibuthe kagesi.

I-clamp bar ehlinzeka ngendlela yokuguquguquka kazibuthe phakathi kwezigxobo zesisekelo sikazibuthe, futhi ngaleyo ndlela ibambe ucezu lomsebenzi we-sheetmetal.

Uthango olugobayo olujikijelwe emaphethelweni angaphambili womzimba kazibuthe futhi luhlinzeka ngendlela yokusebenzisa amandla okugoba kucezu lokusebenza.

Ukucushwa Magnet-Body

Ukucushwa okuhlukahlukene kuyenzeka kumzimba kazibuthe.

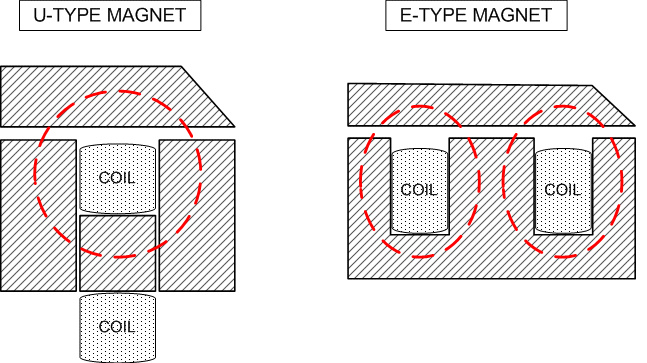

Nazi ezi-2 ezisetshenziswe zombili emishinini yeMagnabend:

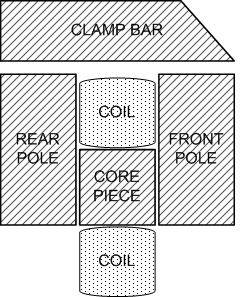

Imigqa ebomvu edayishiwe emidwebeni engenhla imelela izindlela eziguquguqukayo kazibuthe.Qaphela ukuthi idizayini "Yohlobo lwe-U" inendlela eyodwa yokuguquguquka (ipheya elingu-1 lezigxobo) kanti idizayini ye-"E-Type" inemizila engu-2 egelezayo (amapheya angu-2 ezigxobo).

Ukuqhathanisa Ukucushwa Kwezibuthe:

Ukucushwa kohlobo lwe-E kusebenza kahle kakhulu kunokucushwa kohlobo lwe-U.

Ukuze uqonde ukuthi kungani lokhu kunjalo cabangela imidwebo emibili engezansi.

Ngakwesobunxele kunesiphambano sikazibuthe wohlobo lwe-U kanti kwesokudla kunozibuthe wohlobo lwe-E owenziwe ngokuhlanganisa izinhlobo ezi-2 ze-U efanayo.Uma ukucushwa kukazibuthe ngakunye kuqhutshwa ikhoyili ene-ampere-turn efanayo ngokusobala uzibuthe ophindwe kabili (uhlobo lwe-E) uzoba namandla okubamba aphindwe kabili.Isebenzisa futhi insimbi ephindwe kabili kodwa ayisekho ucingo lwekhoyili!(Kucatshangelwa umklamo wekhoyili ende).

(Inani elincane locingo olwengeziwe lizodingeka kuphela ngoba imilenze emibili yekhoyili iqhelelene kakhulu ekwakhiweni kwe-"E", kodwa lena eyengeziwe iba yinto engasho lutho ekwakhiweni kwekhoyili ende njengaleyo esetshenziswa kwi-Magnabend).

I-Super Magnabend:

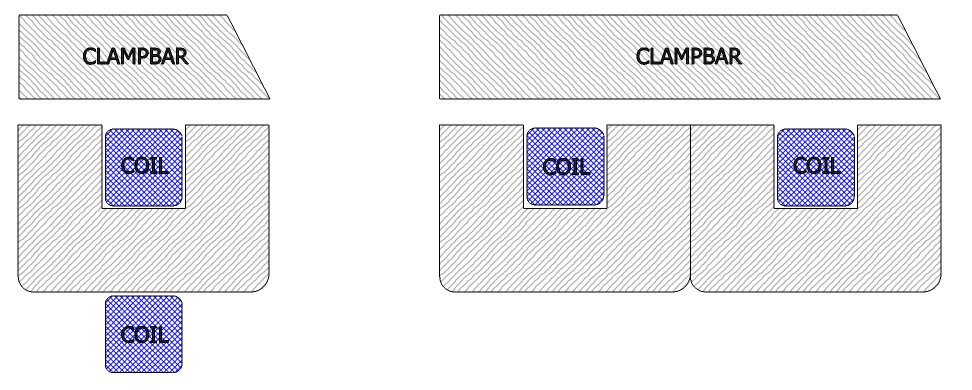

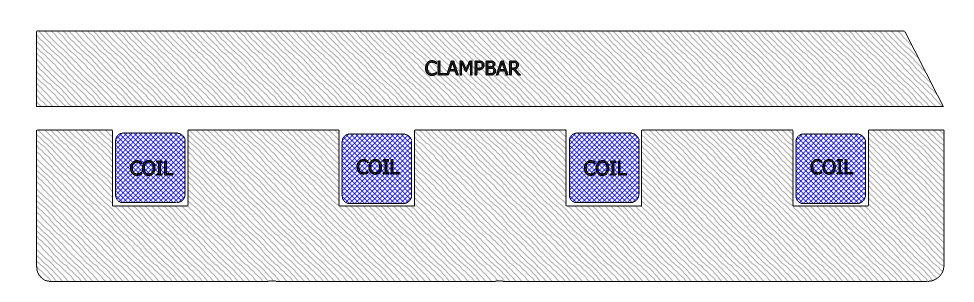

Ukwakha uzibuthe onamandla nakakhulu umqondo "E" unganwetshwa njengalokhu kucushwa kwe-double-E:

Imodeli ye-3-D:

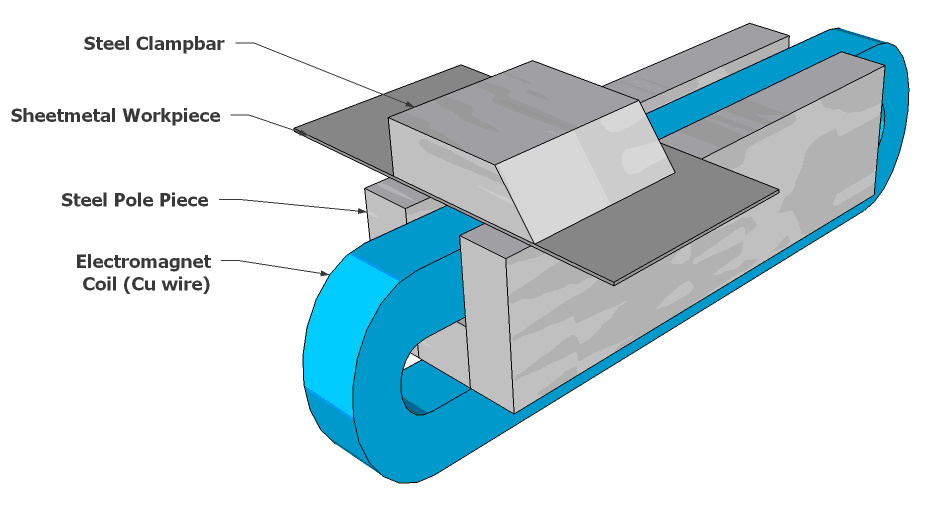

Ngezansi umdwebo ongu-3-D obonisa ukuhlelwa okuyisisekelo kwezingxenye zikazibuthe wohlobo lwe-U:

Kulo mklamo izigxobo zangaphambili nezasemuva ziyizicucu ezihlukene futhi zixhunywe ngamabhawudi esiqeshini se-Core.

Nakuba ngokomthetho, bekungenzeka umshini wohlobo lukazibuthe wohlobo lwe-U ocezwini olulodwa lwensimbi, bekungeke-ke kwenzeke ukufaka ikhoyili futhi ngaleyo ndlela ikhoyili kufanele ilimele endaweni (emzimbeni ozibuthe owenziwe ngomshini. ).

Esimeni sokukhiqiza kuyinto efiselekayo kakhulu ukukwazi ukuphendukisa amakhoyili ngokuhlukana (ku-former ekhethekile).Ngakho-ke idizayini yohlobo lwe-U ilawula ngempumelelo ukwakhiwa okwenziwe.

Ngakolunye uhlangothi umklamo wohlobo lwe-E uziboleka kahle emzimbeni kazibuthe owenziwe ocezwini olulodwa lwensimbi ngoba ikhoyili eyakhiwe ngaphambili ingafakwa kalula ngemva komshini ozibuthe.Umzimba kazibuthe onesiqephu esisodwa nawo usebenza kangcono ngozibuthe njengoba ungenazo izikhala zokwakha ezinganciphisa ukugeleza kazibuthe (ngakho-ke amandla okubamba) kancane.

(AmaMagnabend amaningi enziwe ngemuva kuka-1990 asebenzisa ukwakheka kohlobo lwe-E).

Ukukhethwa Kwempahla Yokwakhiwa Kwezibuthe

Umzimba kazibuthe kanye ne-clampbar kumele kwenziwe ngezinto ze-ferromagnetic (magnetisable).Insimbi iyimpahla eshibhe kakhulu ye-ferromagnetic futhi iyisinqumo esisobala.Kodwa-ke kunezinhlobonhlobo zensimbi ezikhethekile ezitholakalayo ezingase zicatshangelwe.

1) I-Silicon Steel : Insimbi ephezulu yokuphikiswa okuvame ukutholakala kuma-laminations amancane futhi isetshenziswa kuma-AC transformers, amamagnethi e-AC, ama-relay njll. Izakhiwo zayo azidingeki ku-Magnabend okuyi-DC magnet.

2) Insimbi Ethambile : Le nto izobonisa uzibuthe oyinsalela ephansi okungaba kuhle emshinini weMagnabend kodwa ithambe ngokomzimba okusho ukuthi izobotshwa kalula futhi ilimale;kungcono ukuxazulula inkinga ye-magnetism eyinsalela ngenye indlela.

3) I-Cast Iron : Ayifakwa kalula uzibuthe njengensimbi egoqiwe kodwa ingacatshangwa.

I-4) Uhlobo Lwensimbi Engagqwali 416 : Ayikwazi ukufakwa uzibuthe ngokuqinile njengensimbi futhi ibiza kakhulu (kodwa ingase ibe usizo endaweni encane yokuvikela evikelayo emzimbeni kazibuthe).

5) Uhlobo Lwensimbi Engagqwali 316 : Lena ingxubevange yensimbi engeyona-magnetic ngakho-ke ayifaneleki nhlobo (ngaphandle kokuthi ku-4 ngenhla).

6) I-Medium Carbon Steel, thayipha i-K1045: Le nto ifaneleka ngokugqamile ukwakhiwa kukazibuthe, (nezinye izingxenye zomshini).Iqinile ngendlela efanelekile esimweni esinikeziwe futhi isebenza kahle nemishini.

7) Uhlobo lwe-Medium Carbon Steel CS1020 : Le nsimbi ayiqinile kangako njenge-K1045 kodwa itholakala kalula futhi ngaleyo ndlela ingaba yisinqumo esiwusizo kakhulu sokwakhiwa komshini weMagnabend.

Qaphela ukuthi izici ezibalulekile ezidingekayo yilezi:

High saturation uzibuthe.(Ama-alloys amaningi ensimbi agcwala cishe ku-2 Tesla),

Ukutholakala kosayizi besigaba abawusizo,

Ukumelana nomonakalo wengozi,

Ukukwazi, kanye

Izindleko ezinengqondo.

Insimbi ye-carbon emaphakathi ihambisana kahle nazo zonke lezi zidingo.Insimbi enekhabhoni ephansi ingasetshenziswa futhi kodwa ayimelani nomonakalo owenzekile.Kukhona futhi amanye ama-alloys akhethekile, afana ne-supermendur, ane-saturation magnetisation ephakeme kodwa akufanele acatshangelwe ngenxa yezindleko zawo eziphakeme kakhulu uma ziqhathaniswa nensimbi.

Insimbi ye-carbon emaphakathi iyabonisa nokho uzibuthe osalayo okwanele ukuba uhlupho.(Bheka isigaba esithi Residual Magnetism).

Ikhoyili

Ikhoyili yiyona eshayela i-magnetising flux ku-electromagnetic.Amandla ayo azibuthe angumkhiqizo nje wenombolo yokujika (N) kanye nekhoyili yamanje (I).Ngakho:

N = inani lamajika

I = current in the windings.

Ukuvela kuka "N" kufomula engenhla kuholela embonweni oyiphutha ojwayelekile.

Kucatshangwa kabanzi ukuthi ukwandisa inani lokujika kuzokwandisa amandla kazibuthe kodwa ngokuvamile lokhu akwenzeki ngoba ukuphenduka okungeziwe kunciphisa okwamanje, I.

Cabangela ikhoyili enikezwa i-voltage ye-DC engashintshi.Uma inani lokuphenduka liphindwe kabili khona-ke ukumelana kwama-windings kuzophinde kuphindwe kabili (ku-coil ende) futhi ngaleyo ndlela okwamanje kuzobe kuhhafu.Umphumela awukho ukwanda kwe-NI.

Okunquma ngempela i-NI ukumelana nokujika ngakunye.Ngakho-ke, ukuze kwandiswe i-NI ubukhulu bocingo kufanele kwandiswe.Inani lokujika okwengeziwe ukuthi anciphisa amandla amanje ngakho-ke ukuchithwa kwamandla kukhoyili.

Umklami kufanele akhumbule ukuthi i-wire gauge yiyona enquma amandla kazibuthe ekhoyili.Lena ipharamitha ebaluleke kakhulu yokuklama ikhoyili.

Umkhiqizo we-NI uvame ukubizwa ngokuthi "i-ampere turns" yekhoyili.

Mangaki ama-Ampere Turns adingekayo?

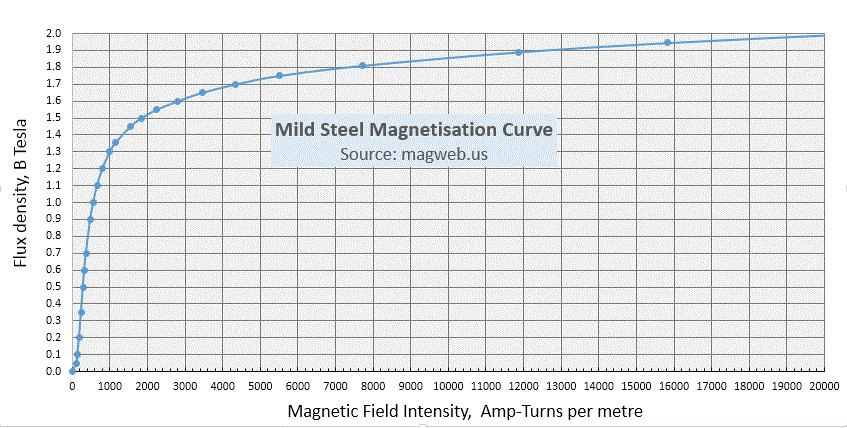

Insimbi ikhombisa ukugcwala kwamagnetisa cishe kwe-2 Tesla futhi lokhu kusetha umkhawulo obalulekile wokuthi mangakanani amandla okubamba angatholwa.

Kusukela kugrafu engenhla sibona ukuthi amandla enkambu adingekayo ukuze uthole ukuminyana kwe-flux ye-2 Tesla cishe i-20,000 ampere-turns imitha ngayinye.

Manje, ngomklamo ojwayelekile we-Magnabend, ubude bendlela yokuguquguquka ensimbi bungaba ngu-1/5 wemitha ngakho-ke kuzodinga (20,000/5) AT ukukhiqiza ukugcwaliswa kwe-saturation, okungaba ngu-4,000 AT.

Kungaba kuhle ukuba namajika amaningi e-ampere kunalokhu ukuze ukugcwaliswa kukazibuthe kugcinwe ngisho nalapho izikhala ezingezona ezikazibuthe (okungukuthi ama-workpieces angewona ayoni) zethulwa kumjikelezo kazibuthe.Kodwa-ke amajika e-ampere engeziwe angatholwa kuphela ngezindleko ezinkulu zokuchithwa kwamandla noma izindleko zocingo lwethusi, noma kokubili.Ngakho kudingeka ukuvumelana.

Imiklamo ejwayelekile ye-Magnabend inekhoyili ekhiqiza ama-ampere angu-3,800.

Qaphela ukuthi lesi sibalo asincikile kubude bomshini.Uma idizayini kazibuthe efanayo isetshenziswa phezu kwebanga lobude bomshini kusho ukuthi imishini emide izoba nokujika okumbalwa kocingo olukhulu.Azodweba inani lamanje elithe xaxa kodwa azoba nomkhiqizo ofanayo wokujika kwama-amps x futhi azoba namandla okubamba afanayo (kanye nokuchithwa kwamandla afanayo) ngeyunithi ngayinye yobude.

Duty Cycle

Umqondo womjikelezo womsebenzi uyingxenye ebaluleke kakhulu yokwakheka kukazibuthe kagesi.Uma umklamo uhlinzeka ngomjikelezo omningi womsebenzi kunalokho odingekayo kusho ukuthi awukho ulungile.Umjikelezo womsebenzi owengeziwe ngokwemvelo usho ukuthi kuzodingeka intambo yethusi eyengeziwe (okuhambisana nezindleko eziphakeme) kanye/noma kuzoba namandla okubamba amancane atholakalayo.

Qaphela: Umazibuthe womjikelezo womsebenzi ophezulu uzoba nokuchithwa kwamandla amancane okusho ukuthi uzosebenzisa amandla amancane futhi ngaleyo ndlela kube ishibhile ukuwusebenza.Nokho, ngenxa yokuthi uzibuthe UVULIWE isikhathi esifushane kuphela izindleko zamandla okusebenza ngokuvamile zithathwa njengezinokubaluleka okuncane kakhulu.Ngakho indlela yokuklama iwukuba nokuchitha amandla amaningi ngendlela ongabalekela ngayo ngokungashisi ngokweqile ama-winding ekhoyili.(Le ndlela ivamile emiklamo eminingi kazibuthe).

I-Magnabend yakhelwe umjikelezo womsebenzi ongaba ngu-25%.

Ngokuvamile kuthatha imizuzwana emi-2 noma emi-3 kuphela ukwenza ukugoba.Umazibuthe uzocisha eminye imizuzwana eyi-8 kuye kweyi-10 ngenkathi indawo yokusebenza ibekwa kabusha futhi iqondaniswe isilungele ukugoba okulandelayo.Uma umjikelezo womsebenzi wama-25% weqiwa lapho-ke ekugcineni uzibuthe uzoshisa kakhulu futhi ukugcwala okushisayo kuzokhubeka.Umazibuthe ngeke wonakaliswe kodwa kuzodingeka uvunyelwe ukuba uphole cishe imizuzu engama-30 ngaphambi kokuba usetshenziswe futhi.

Isipiliyoni sokusebenza ngemishini emkhakheni sibonise ukuthi umjikelezo womsebenzi wama-25% wanele kubasebenzisi abajwayelekile.Eqinisweni abanye abasebenzisi bacele izinguqulo zokuzikhethela zamandla aphezulu aphezulu omshini onamandla okuphoqa okwengeziwe ngezindleko zomjikelezo wemisebenzi encane.

I-Coil Cross-Sectional Area

Indawo ye-cross sectional etholakalayo yekhoyili iyona ezonquma inani eliphezulu lezintambo zethusi ezingafakwa. Indawo etholakalayo akufanele ibe ngaphezu kwesidingo, ihambisane nokujika kwe-ampere okudingekayo kanye nokuchithwa kwamandla.Ukunikeza indawo ethe xaxa yekhoyili kuyokwandisa ngokungenakugwenywa ubukhulu bemagnethi futhi kubangele ubude bendlela yokuguquguquka ensimbi (okuzonciphisa ukuguquguquka okuphelele).

Ingxabano efanayo isho ukuthi noma iyiphi indawo yekhoyili enikeziwe ekwakhiweni kwayo kufanele ihlale igcwele ucingo lwethusi.Uma ingagcwele kusho ukuthi ijometri kazibuthe ibingaba ngcono.

I-Magnabend Clamping Force:

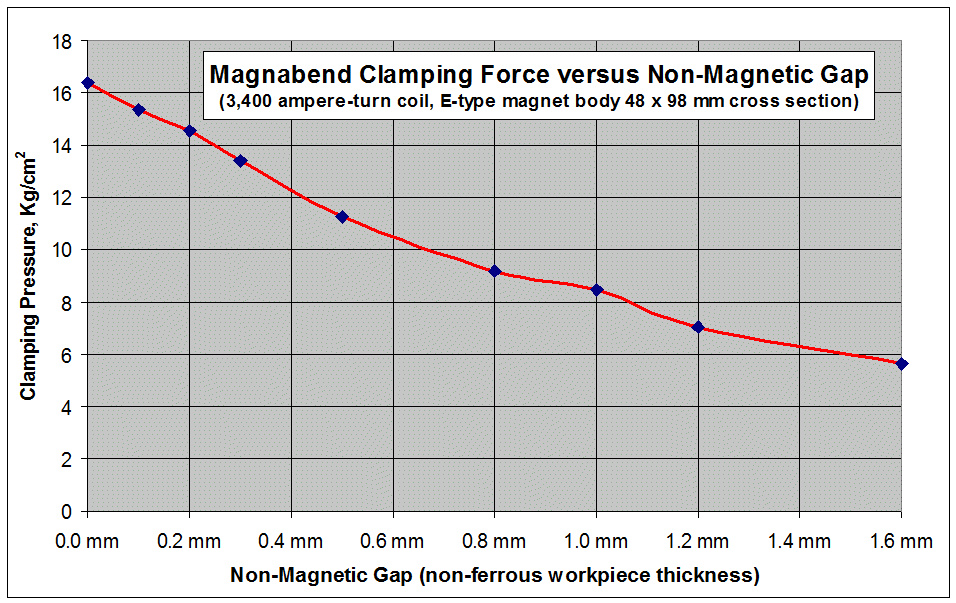

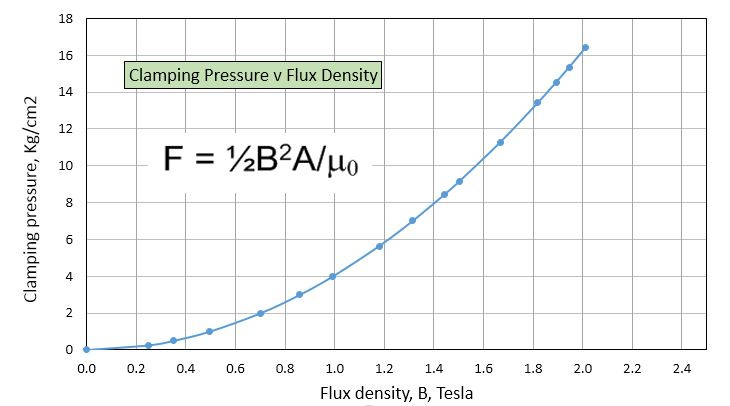

Igrafu engezansi itholwe ngezilinganiso zokuhlola, kodwa ivumelana kahle nezibalo zethiyori.

Amandla okubamba angabalwa ngokwezibalo kusukela kule fomula:

F = amandla ku-Newtons

B = ukuminyana kazibuthe ku-Teslas

A = indawo yezigxobo ku-m2

µ0 = ukuqina kazibuthe okungaguquki, (4π x 10-7)

Isibonelo sizobala amandla okubamba we-flux density ye-2 Tesla:

Ngakho F = ½ (2)2 A/µ0

Ukuze uthole amandla endaweni yeyunithi (ingcindezi) singaphonsa u-"A" kufomula.

Ngakho Ingcindezi = 2/µ0 = 2/(4π x 10-7) N/m2.

Lokhu kuphuma ku-1,590,000 N/m2.

Ukuguqula lokhu kube amakhilogremu kuphoqa kungahlukaniswa ngo-g (9.81).

Ngakho: Ingcindezi = 162,080 kg/m2 = 16.2 kg/cm2.

Lokhu kuvumelana kahle namandla akaliwe egebe elinguziro eliboniswe kugrafu engenhla.

Lesi sibalo singaguqulwa kalula sibe amandla okuphoqa ingqikithi yomshini owunikeziwe ngokuwuphindaphinda ngendawo yesigxobo yomshini.Kumodeli we-1250E indawo yesigxobo yi-125 (1.4 + 3.0 + 1.5) = 735 cm2.

Ngakho ingqikithi, i-zero-gap, amandla azoba (735 x 16.2) = 11,900 kg noma amathani angu-11.9;cishe amathani angu-9.5 imitha yobude bukazibuthe.

Ukuminyana kwe-Flux kanye nengcindezi ye-Clamping kuhlobene ngokuqondile futhi kuboniswe kugrafu engezansi:

Amandla Okuqinisa Okusebenzayo:

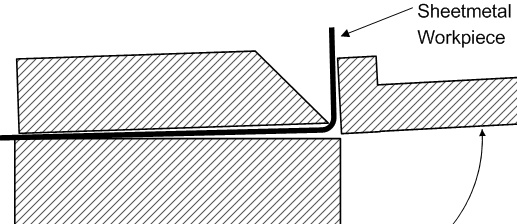

Ngokwenza la mandla okugoqa aphezulu abonakala kuphela lapho engadingeki(!), okungukuthi lapho kugoba izingcezu zensimbi ezacile.Lapho ugoba ama-workpieces angeyona insimbi amandla azoba mancane njengoba kukhonjisiwe kugrafu engenhla, futhi (ngokumangazayo), aphinde abe mancane lapho kugotshwa izinsimbi zokusebenza eziwugqinsi.Lokhu kungenxa yokuthi amandla okubamba adingekayo ukuze enze ijika elicijile aphakeme kakhulu kunalawo adingekayo ukuze kube nokugoba okuphakathi.Ngakho-ke okwenzekayo ukuthi njengoba ukugoba kuqhubeka umphetho wangaphambili we-clampbar uphakamisa kancane ngaleyo ndlela uvumela ucezu lokusebenza ukuthi lwakhe irediyasi.

Igebe elincane lomoya elakhekayo lidala ukulahlekelwa kancane kwamandla okubamba kodwa amandla adingekayo ukuze kwakheke i-radius bend ehle kakhulu kunamandla okubamba uzibuthe.Ngaleyo ndlela kuba nesimo esizinzile futhi i-clampbar ayikuyeki.

Okuchazwe ngenhla indlela yokugoba lapho umshini useduze nomkhawulo wawo wokujiya.Uma kuzanywa ucezu olubanzi nakakhulu, khona-ke i-clampbar izosuka.

Lo mdwebo uphakamisa ukuthi uma unqenqema lwekhala le-clampbar belunwetshwe kancane, kunokuba lube bukhali, igebe lomoya lokugoba okuwugqinsi belizoncishiswa.

Impela kunjalo futhi i-Magnabend eyenziwe kahle izoba ne-clampbar enomkhawulo obanzi.(Unqenqema olune-radiused nalo luncane kakhulu ekulimaleni kwengozi uma kuqhathaniswa nonqenqema olucijile).

Imodi Eseceleni Yokwehluleka Ukugoba:

Uma kuzanywa ukugoba endaweni yokusebenza ewugqinsi kakhulu umshini uzohluleka ukuyigoba ngoba i-clampbar izovele isuke.(Ngenhlanhla lokhu akwenzeki ngendlela emangalisayo; i-clampbar ivele iyeke ithule).

Kodwa-ke uma umthwalo ogobayo ungaphezudlwana komthamo kakazibuthe ngokuvamile okwenzekayo ukuthi ukugoba kuzoqhubeka nokusho cishe amadigri angu-60 bese i-clampbar izoqala ukushelela ihlehle.Kule ndlela yokwehluleka uzibuthe angamelana kuphela nomthwalo ogobayo ngokungaqondile ngokudala ukungqubuzana phakathi kwendawo yokusebenza nombhede kazibuthe.

Umehluko wogqinsi phakathi kokwehluleka ngenxa yokuphakanyiswa kanye nokwehluleka ngenxa yokushelela ngokuvamile awumuningi kakhulu.

Ukwehluleka ukuphakamisa kungenxa yocezu lokusebenza olunyakazisa unqenqema lwangaphambili lwe-clampbar phezulu.Amandla okubamba emaphethelweni angaphambili e-clampbar yiwo ikakhulukazi amelana nalokhu.Ukugoqa emaphethelweni angemuva kunomphumela omncane ngoba kuseduze nalapho i-clampbar iphinyiswa khona.Eqinisweni yingxenye kuphela yamandla okuphoqa aphelele amelana nokusuka.

Ngakolunye uhlangothi ukuslayida kumelana namandla okubamba aphelele kodwa ngokungqubuzana kuphela ukuze ukumelana kwangempela kuncike ku-coefficient of friction phakathi kwendawo yokusebenza kanye nobuso bukazibuthe.

Ngensimbi ehlanzekile neyomile i-friction coefficient ingaba phezulu ngokufika ku-0.8 kodwa uma ukuthambisa kukhona khona-ke kungase kube phansi njengo-0.2.Imvamisa kuzoba ndawana thize phakathi kokuthi imodi eseceleni yokwehluleka ukugoba ivamise ukuba ngenxa yokushelela, kodwa imizamo yokwandisa ukungqubuzana ebusweni bukazibuthe itholwe ingafaneleki.

Amandla Okuqina:

Ngomzimba kazibuthe wohlobo lwe-E ongu-98mm ububanzi no-48mm ukushona kanye nekhoyili engu-3,800 ampere-turn, umthamo ophelele wokugoba ngu-1.6mm.Lokhu ukujiya kusebenza kokubili ishidi lensimbi kanye neshidi le-aluminium.Kuzoba nokucisha kancane eshidini le-aluminium kodwa kudinga i-torque encane ukuligoba ukuze lokhu kunxephezele ngendlela yokuthi kunikeze umthamo wegeji ofanayo wazo zombili izinhlobo zensimbi.

Kudingeka kube nezixwayiso kumthamo oshiwo wokugoba: Okuyinhloko ukuthi amandla okukhiqiza eshidi lensimbi angahluka kakhulu.Umthamo we-1.6mm usebenza kunsimbi enengcindezi yesivuno efinyelela ku-250 MPa kanye naku-aluminium enengcindezi yokukhiqiza efinyelela ku-140 MPa.

Umthamo wokujiya ensimbi engagqwali cishe u-1.0mm.Lawa mandla mancane kakhulu kunezinye izinsimbi eziningi ngoba insimbi engagqwali ngokuvamile ayiyona i-magnetic kodwa inokucindezeleka kokuvunwa okuphezulu.

Esinye isici izinga lokushisa uzibuthe.Uma uzibuthe uye wavunyelwa ukuba ashise khona-ke ukumelana kwekhoyili kuzoba phezulu futhi lokhu kuzoyibangela ukuthi idonse amandla amancane ngokulandela ama-ampere-turn aphansi kanye namandla okugoqa aphansi.(Lo mphumela ngokuvamile umaphakathi futhi cishe ngeke ubangele umshini ukuthi ungahlangabezani nezincazelo zawo).

Ekugcineni, umthamo omkhulu wama-Magnabend ungenziwa uma ingxenye yesiphambano sikazibuthe yenziwe yaba nkulu.