I-Basic Magnet Design

Umshini we-Magnabend uklanywe njengozibuthe we-DC onamandla onomjikelezo womsebenzi olinganiselwe.

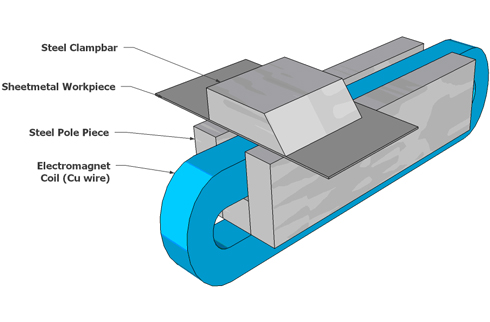

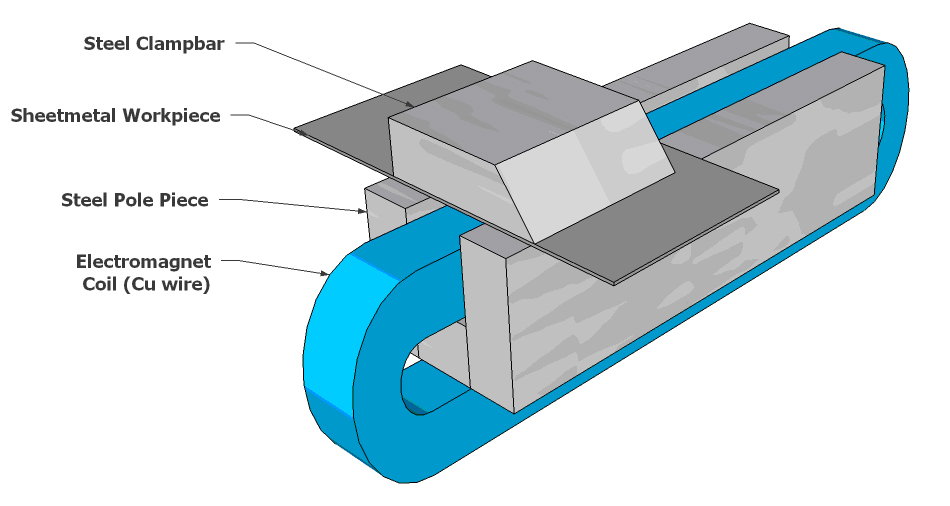

Umshini uqukethe izingxenye ezi-3 eziyisisekelo: -

Umzimba kazibuthe owakha isisekelo somshini futhi uqukethe ikhoyili kazibuthe kagesi.

I-clamp bar ehlinzeka ngendlela yokuguquguquka kazibuthe phakathi kwezigxobo zesisekelo sikazibuthe, futhi ngaleyo ndlela ibambe ucezu lomsebenzi we-sheetmetal.

Uthango olugobayo olujikijelwe emaphethelweni angaphambili womzimba kazibuthe futhi luhlinzeka ngendlela yokusebenzisa amandla okugoba kucezu lokusebenza.

Imodeli ye-3-D:

Ngezansi umdwebo ongu-3-D obonisa ukuhlelwa okuyisisekelo kwezingxenye zikazibuthe wohlobo lwe-U:

Duty Cycle

Umqondo womjikelezo womsebenzi uyingxenye ebaluleke kakhulu yokwakheka kukazibuthe kagesi.Uma umklamo uhlinzeka ngomjikelezo omningi womsebenzi kunalokho odingekayo kusho ukuthi awukho ulungile.Umjikelezo womsebenzi owengeziwe ngokwemvelo usho ukuthi kuzodingeka intambo yethusi eyengeziwe (okuhambisana nezindleko eziphakeme) kanye/noma kuzoba namandla okubamba amancane atholakalayo.

Qaphela: Umazibuthe womjikelezo womsebenzi ophezulu uzoba nokuchithwa kwamandla amancane okusho ukuthi uzosebenzisa amandla amancane futhi ngaleyo ndlela kube ishibhile ukuwusebenza.Nokho, ngenxa yokuthi uzibuthe UVULIWE isikhathi esifushane kuphela izindleko zamandla okusebenza ngokuvamile zithathwa njengezinokubaluleka okuncane kakhulu.Ngakho indlela yokuklama iwukuba nokuchitha amandla amaningi ngendlela ongabalekela ngayo ngokungashisi ngokweqile ama-winding ekhoyili.(Le ndlela ivamile emiklamo eminingi kazibuthe).

I-Magnabend yakhelwe umjikelezo womsebenzi ongaba ngu-25%.

Ngokuvamile kuthatha imizuzwana emi-2 noma emi-3 kuphela ukwenza ukugoba.Umazibuthe uzocisha eminye imizuzwana eyi-8 kuye kweyi-10 ngenkathi indawo yokusebenza ibekwa kabusha futhi iqondaniswe isilungele ukugoba okulandelayo.Uma umjikelezo womsebenzi wama-25% weqiwa lapho-ke ekugcineni uzibuthe uzoshisa kakhulu futhi ukugcwala okushisayo kuzokhubeka.Umazibuthe ngeke wonakaliswe kodwa kuzodingeka uvunyelwe ukuba uphole cishe imizuzu engama-30 ngaphambi kokuba usetshenziswe futhi.

Isipiliyoni sokusebenza ngemishini emkhakheni sibonise ukuthi umjikelezo womsebenzi wama-25% wanele kubasebenzisi abajwayelekile.Eqinisweni abanye abasebenzisi bacele izinguqulo zokuzikhethela zamandla aphezulu aphezulu omshini onamandla okuphoqa okwengeziwe ngezindleko zomjikelezo wemisebenzi encane.

I-Magnabend Clamping Force:

Amandla Okuqinisa Okusebenzayo:

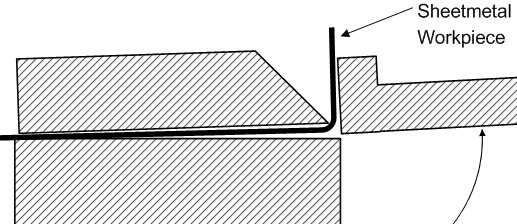

Ngokwenza la mandla okugoqa aphezulu abonakala kuphela lapho engadingeki(!), okungukuthi lapho kugoba izingcezu zensimbi ezacile.Lapho ugoba ama-workpieces angeyona insimbi amandla azoba mancane njengoba kukhonjisiwe kugrafu engenhla, futhi (ngokumangazayo), aphinde abe mancane lapho kugotshwa izinsimbi zokusebenza eziwugqinsi.Lokhu kungenxa yokuthi amandla okubamba adingekayo ukuze enze ijika elicijile aphakeme kakhulu kunalawo adingekayo ukuze kube nokugoba okuphakathi.Ngakho-ke okwenzekayo ukuthi njengoba ukugoba kuqhubeka umphetho wangaphambili we-clampbar uphakamisa kancane ngaleyo ndlela uvumela ucezu lokusebenza ukuthi lwakhe irediyasi.

Igebe elincane lomoya elakhekayo lidala ukulahlekelwa kancane kwamandla okubamba kodwa amandla adingekayo ukuze kwakheke i-radius bend ehle kakhulu kunamandla okubamba uzibuthe.Ngaleyo ndlela kuba nesimo esizinzile futhi i-clampbar ayikuyeki.

Okuchazwe ngenhla indlela yokugoba lapho umshini useduze nomkhawulo wawo wokujiya.Uma kuzanywa ucezu olubanzi nakakhulu, khona-ke i-clampbar izosuka.

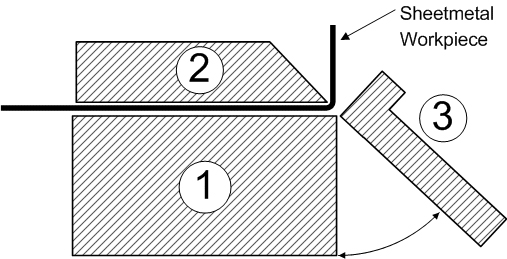

Lo mdwebo uphakamisa ukuthi uma unqenqema lwekhala le-clampbar belunwetshwe kancane, kunokuba lube bukhali, igebe lomoya lokugoba okuwugqinsi belizoncishiswa.

Impela kunjalo futhi i-Magnabend eyenziwe kahle izoba ne-clampbar enomkhawulo obanzi.(Unqenqema olune-radiused nalo luncane kakhulu ekulimaleni kwengozi uma kuqhathaniswa nonqenqema olucijile).

Imodi Eseceleni Yokwehluleka Ukugoba:

Uma kuzanywa ukugoba endaweni yokusebenza ewugqinsi kakhulu umshini uzohluleka ukuyigoba ngoba i-clampbar izovele isuke.(Ngenhlanhla lokhu akwenzeki ngendlela emangalisayo; i-clampbar ivele iyeke ithule).

Kodwa-ke uma umthwalo ogobayo ungaphezudlwana komthamo kakazibuthe ngokuvamile okwenzekayo ukuthi ukugoba kuzoqhubeka nokusho cishe amadigri angu-60 bese i-clampbar izoqala ukushelela ihlehle.Kule ndlela yokwehluleka uzibuthe angamelana kuphela nomthwalo ogobayo ngokungaqondile ngokudala ukungqubuzana phakathi kwendawo yokusebenza nombhede kazibuthe.

Umehluko wogqinsi phakathi kokwehluleka ngenxa yokuphakanyiswa kanye nokwehluleka ngenxa yokushelela ngokuvamile awumuningi kakhulu.

Ukwehluleka ukuphakamisa kungenxa yocezu lokusebenza olunyakazisa unqenqema lwangaphambili lwe-clampbar phezulu.Amandla okubamba emaphethelweni angaphambili e-clampbar yiwo ikakhulukazi amelana nalokhu.Ukugoqa emaphethelweni angemuva kunomphumela omncane ngoba kuseduze nalapho i-clampbar iphinyiswa khona.Eqinisweni yingxenye kuphela yamandla okuphoqa aphelele amelana nokusuka.

Ngakolunye uhlangothi ukuslayida kumelana namandla okubamba aphelele kodwa ngokungqubuzana kuphela ukuze ukumelana kwangempela kuncike ku-coefficient of friction phakathi kwendawo yokusebenza kanye nobuso bukazibuthe.

Ngensimbi ehlanzekile neyomile i-friction coefficient ingaba phezulu ngokufika ku-0.8 kodwa uma ukuthambisa kukhona khona-ke kungase kube phansi njengo-0.2.Imvamisa kuzoba ndawana thize phakathi kokuthi imodi eseceleni yokwehluleka ukugoba ivamise ukuba ngenxa yokushelela, kodwa imizamo yokwandisa ukungqubuzana ebusweni bukazibuthe itholwe ingafaneleki.

Amandla Okuqina:

Ngomzimba kazibuthe wohlobo lwe-E ongu-98mm ububanzi no-48mm ukushona kanye nekhoyili engu-3,800 ampere-turn, umthamo ophelele wokugoba ngu-1.6mm.Lokhu ukujiya kusebenza kokubili ishidi lensimbi kanye neshidi le-aluminium.Kuzoba nokucisha kancane eshidini le-aluminium kodwa kudinga i-torque encane ukuligoba ukuze lokhu kunxephezele ngendlela yokuthi kunikeze umthamo wegeji ofanayo wazo zombili izinhlobo zensimbi.

Kudingeka kube nezixwayiso kumthamo oshiwo wokugoba: Okuyinhloko ukuthi amandla okukhiqiza eshidi lensimbi angahluka kakhulu.Umthamo we-1.6mm usebenza kunsimbi enengcindezi yesivuno efinyelela ku-250 MPa kanye naku-aluminium enengcindezi yokukhiqiza efinyelela ku-140 MPa.

Umthamo wokujiya ensimbi engagqwali cishe u-1.0mm.Lawa mandla mancane kakhulu kunezinye izinsimbi eziningi ngoba insimbi engagqwali ngokuvamile ayiyona i-magnetic kodwa inokucindezeleka kokuvunwa okuphezulu.

Esinye isici izinga lokushisa uzibuthe.Uma uzibuthe uye wavunyelwa ukuba ashise khona-ke ukumelana kwekhoyili kuzoba phezulu futhi lokhu kuzoyibangela ukuthi idonse amandla amancane ngokulandela ama-ampere-turn aphansi kanye namandla okugoqa aphansi.(Lo mphumela ngokuvamile umaphakathi futhi cishe ngeke ubangele umshini ukuthi ungahlangabezani nezincazelo zawo).

Ekugcineni, umthamo omkhulu wama-Magnabend ungenziwa uma ingxenye yesiphambano sikazibuthe yenziwe yaba nkulu.

Isikhathi sokuthumela: Aug-27-2021