Ngokulandela izicelo eziningi manje ngengeza imidwebo enemininingwane yamahinge angenasikhungo iMagnabend kule webhusayithi.

Sicela uqaphele ukuthi lawa mahinge anzima kakhulu ukwenza umshini owodwa.

Izingxenye eziyinhloko zehinji zidinga ukusakaza okunembile (isibonelo ngenqubo yokutshala imali) noma ukwenziwa ngomshini ngezindlela ze-NC.

Ama-Hobbyists akufanele azame ukwenza le hinge.

Nokho abakhiqizi bangathola le midwebo iwusizo kakhulu.

(Ukuze kube lula ukwenza ihinge i-HEMI-HINGE esanda kwakhiwa iyanconywa. Bheka incazelo egcwele nemidwebo lapha).

I-Magnabend CENTRELESS COMPOUND HINGE yasungulwa nguMnuz Geoff Fenton futhi yayinelungelo lobunikazi emazweni amaningi.(Amalungelo obunikazi manje aphelelwe yisikhathi).

Ukwakheka kwalawa mahinge kuvumela umshini weMagnabend ukuthi uvuleke ngokuphelele.

I-beam egobayo izungeza i-eksisi ebonakalayo, ngokuvamile ingaphezulu kancane kwendawo yokusebenza yomshini, futhi uthango lungashwibeka ngokuzungeza okugcwele okungu-180 degrees.

Emidwebeni nasezithombeni ezingezansi kuboniswa kuphela umhlangano wehinge elilodwa.Nokho ukuze kuchazwe i-hinge axis okungenani kufanele kufakwe amahinge ama-2.

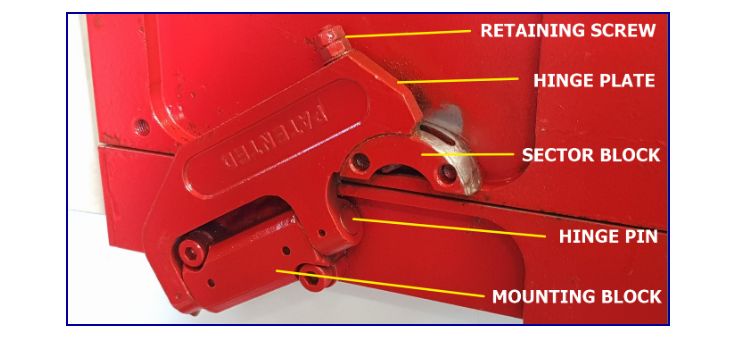

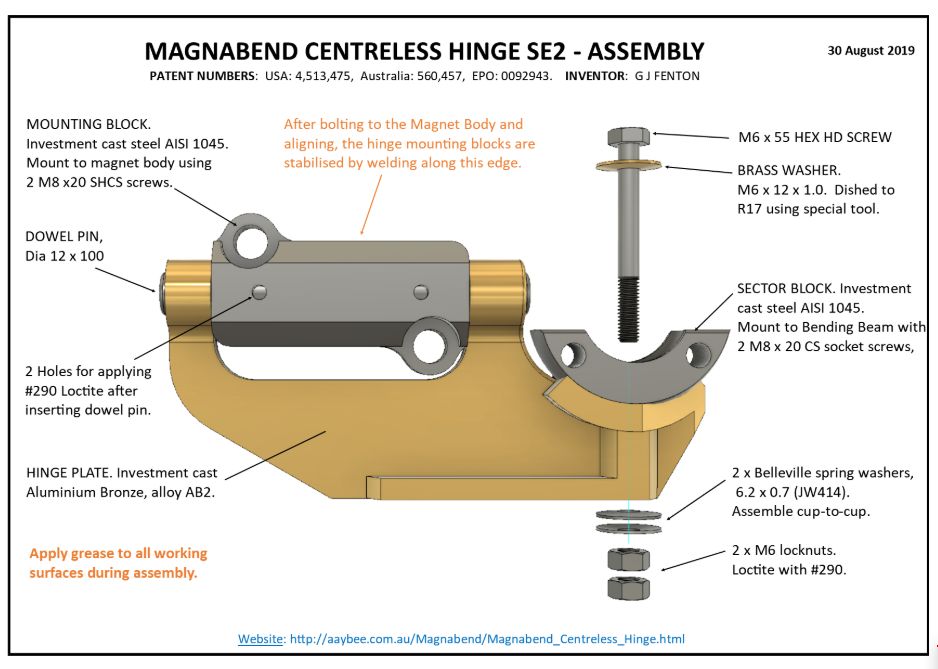

Ukuhlonza I-Hinge Assembly kanye Nezingxenye (ugongolo olugoba kumadigri ayi-180):

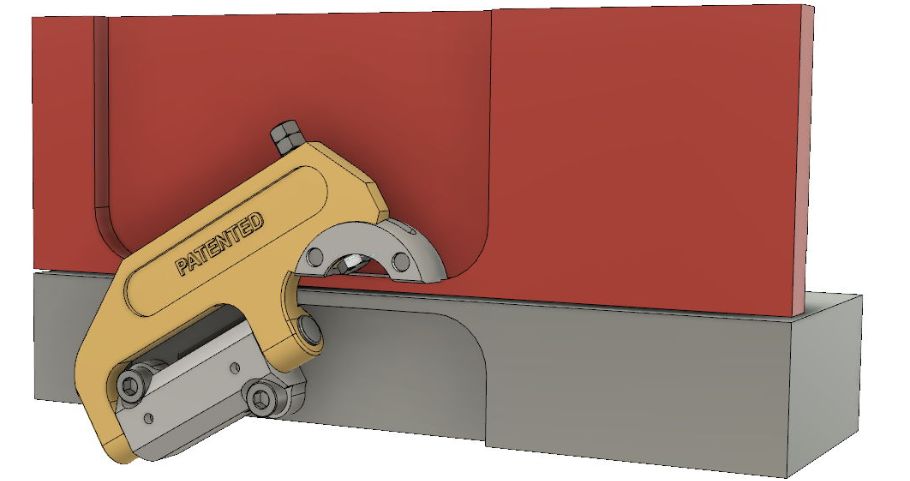

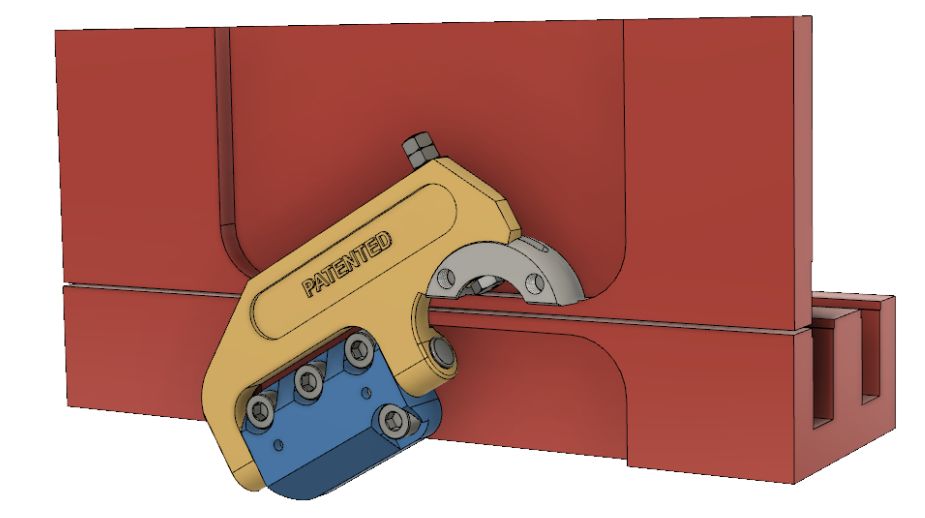

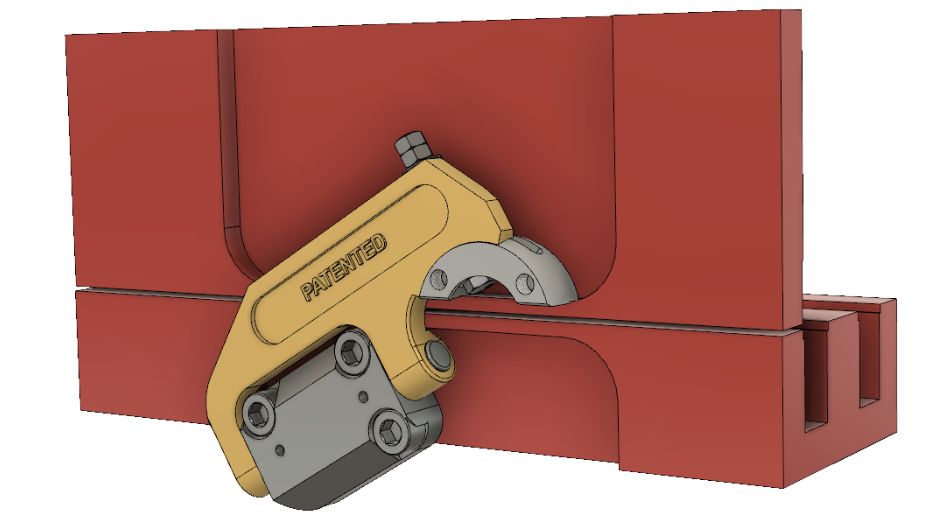

Ihinge ene-Beam egoqayo endaweni ecishe ibe ngu-90 degree:

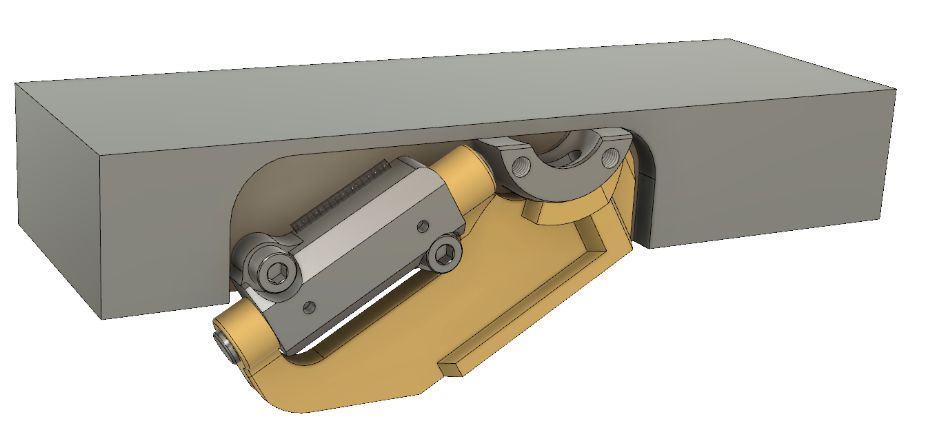

I-Mounted Hinge Assembly -3DModels:

Umdwebo ongezansi uthathwe kumodeli yehinge engu-3-D.

Ngokuchofoza ifayela elilandelayo elithi "ISINYATHELO": I-Mounted Hinge Model.step uzokwazi ukubona imodeli ye-3D.

(Izinhlelo zokusebenza ezilandelayo zizovula .amafayela wesinyathelo: I-AutoCAD, i-Solidworks, i-Fusion360, i-IronCAD noma "kusibukeli" salezo zinhlelo zokusebenza).

Njengoba imodeli ye-3D ivuliwe ungakwazi ukubuka izingxenye kunoma iyiphi i-engeli, usondeze ukuze ubone imininingwane, noma wenze izingxenye ezithile zinyamalale ukuze ukwazi ukubona ezinye izingxenye ngokucacile.Ungenza futhi izilinganiso kunoma yiziphi izingxenye.

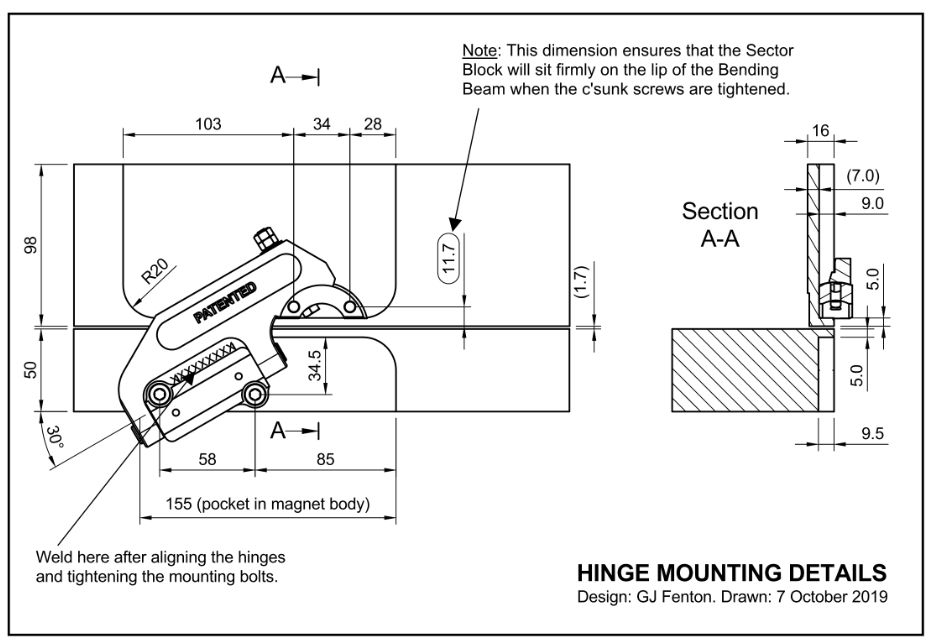

Ubukhulu bokukhweza i-Hinge Assembly:

I-Hinge Assembly:

Chofoza umdwebo ukuze uthole ukubuka okukhulisiwe.Chofoza lapha ukuze uthole ifayela le-pdf: Hinge Assembly.PDF

Imidwebo enemininingwane:

Amafayela emodeli ye-3D (amafayela e-STEP) afakwe ngezansi angasetshenziselwa ukuphrinta kwe-3D noma ukukhiqiza i-Computer Aid Manufacturing (CAM).

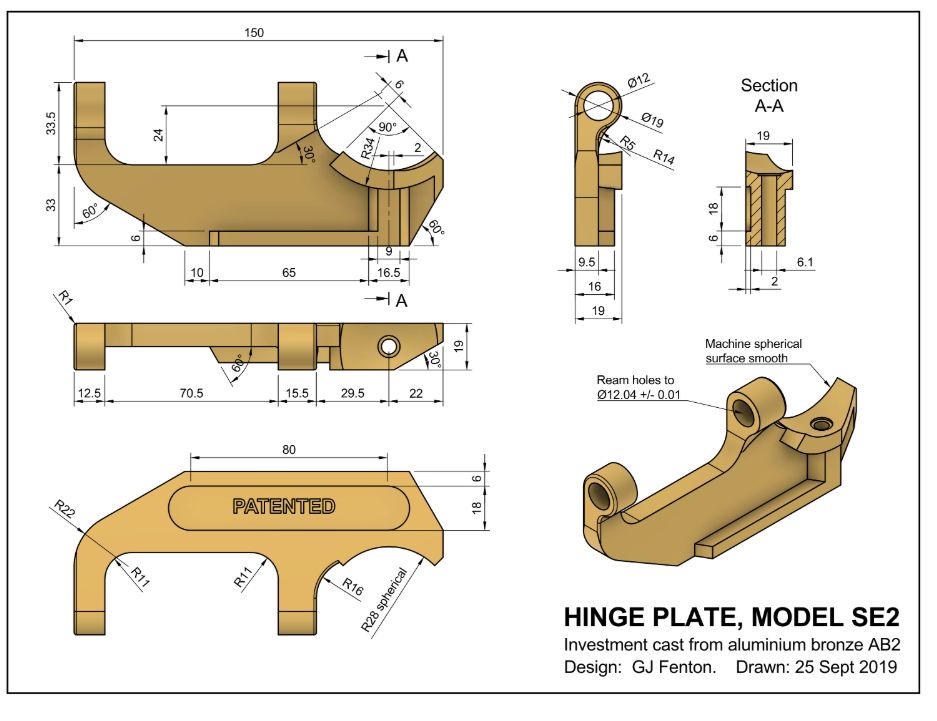

1. I-Hinge Plate:

Chofoza umdwebo ukuze uthole ukubuka okukhulisiwe.Chofoza lapha ukuze uthole ifayela le-pdf: I-Hinge Plate.PDF.Imodeli ye-3D: I-Hinge Plate.step

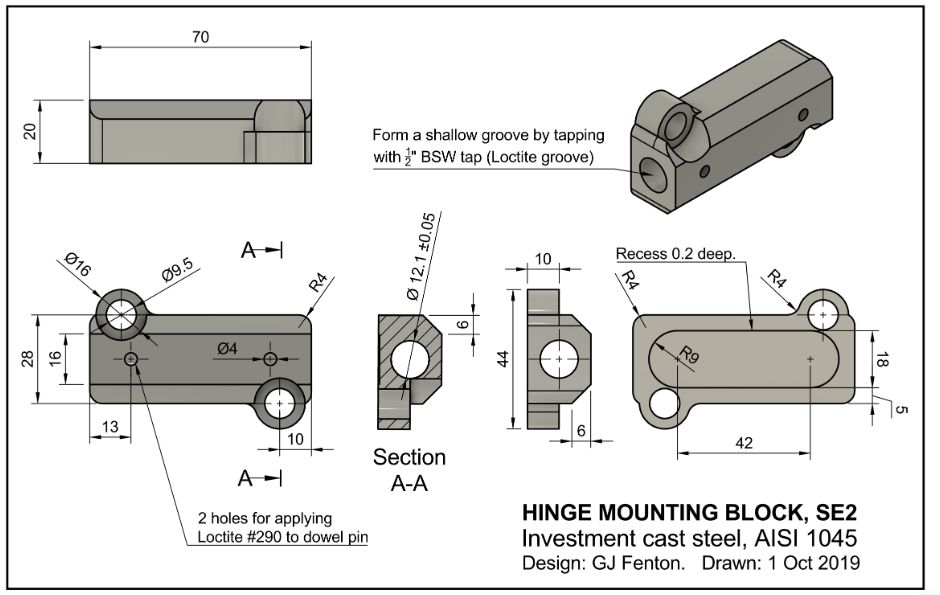

2. Ibhulokhi yokukhweza:

Chofoza umdwebo ukuze ukhulise.Chofoza lapha ukuze uthole ifayela le-pdf: Mounting_Block-welded.PDF, 3D Model: MountingBlock.step

I-Mounting Block impahla yi-AISI-1045.Le nsimbi ye-carbon ephezulu ikhethwa ngenxa yamandla ayo aphezulu kanye nokumelana nokushwibeka eduze kwembobo yephini lehinge.

Sicela uqaphele ukuthi le block yokukhweza ihinge yakhelwe ukuthi iqiniswe ngokushiselwa emzimbeni kazibuthe kulandela ukuqondana kokugcina.

Futhi qaphela ukucaciswa kwentambo engashoni ngaphakathi kwembobo yephini lehinge.Lolu chungechunge luhlinzeka ngesiteshi se-wick-in Loctite esisetshenziswa ngesikhathi sokuhlanganiswa kwamahinge.(Izikhonkwane zamahinge zinokuthambekela okunamandla kokusebenza ngaphandle uma zivaleke kahle ngaphakathi).

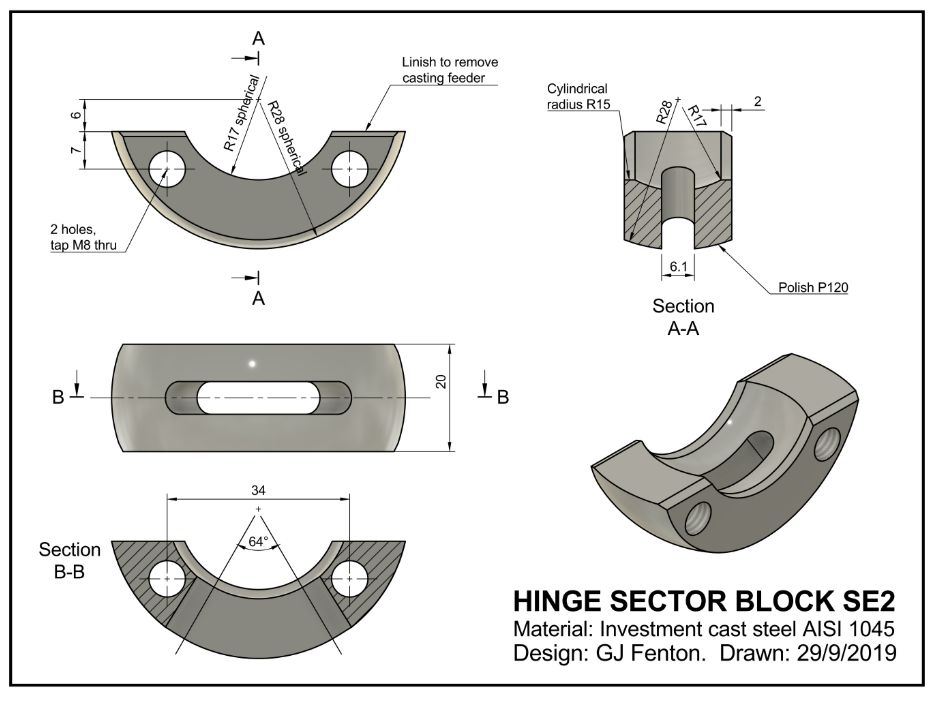

3. I-Sector Block:

Chofoza umdwebo ukuze uthole ukubuka okukhulisiwe.Chofoza lapha ukuze uthole ifayela le-pdf: I-Sector Block.PDF, ifayela le-3D Cad: I-SectorBlock.step

4. Iphinikhodi yehinge:

Iphinikhodi yedowel yensimbi eqinile nephansi.

AMAHINGA ABOSHIWE

Emidwebeni nasemamodelini ngenhla kokuhlanganiswa kwehinge kubhawudilwe ku-Gonga Beam (ngezikulufu ku-Sector Block) kodwa okunamathiselwe ku-Magnet Body kuncike ekubhodeni FUTHI.

Ukuhlanganiswa kwehinge kungaba lula kakhulu ukwenziwa nokufaka uma ukushisela kungadingeki.

Ngesikhathi sokuthuthukiswa kwehinge sithole ukuthi asikwazanga ukuthola ukungqubuzana okwanele ngamabhawudi wodwa ukuze siqinisekise ukuthi ibhlokhi ekhwezayo ngeke ishelele lapho kufakwa imithwalo ephezulu yendawo.

Qaphela:Ama-shanks amabhawodi ngokwawo awavimbeli ukushelela kwe-Mounting Block ngoba amabhawodi asezimbotsheni ezinkulu kakhulu.Ukususwa emigodini kuyadingeka ukuhlinzeka ngokulungiswa nokungalungile okuncane ezikhundleni.

Kodwa-ke siye sanikezela ngamahinge aboshwe ngokugcwele ohlu lwemishini ekhethekile yeMagnabend eyayiklanyelwe imigqa yokukhiqiza.

Kuleyo mishini imithwalo yamahinge yayimaphakathi futhi ichazwe kahle futhi ngenxa yalokho amahinge aboshwe asebenza kahle.

Emdwebeni ongezansi kwe-Mounting Block (umbala oluhlaza okwesibhakabhaka) uklanyelwe ukwamukela amabhawodi e-M8 amane (kunokuba amabhawodi amabili e-M8 kanye nokushisela).

Lona bekuwumklamo osetshenziselwa imishini yokukhiqiza iMagnabend.

(Senza cishe engu-400 yaleyo mishini ekhethekile enobude obuhlukahlukene ikakhulukazi phakathi nawo-1990).

Sicela uqaphele ukuthi amabhawodi amabili aphezulu e-M8 angena esigxotsheni esingaphambili somzimba kazibuthe ongu-7.5mm kuphela ubukhulu endaweni engaphansi kwephakethe lehinge.

Ngakho-ke lezi zikulufi akumele zeqe ku-16mm ubude (9mm kubhlokhi yokukhweza kanye no-7mm emzimbeni kazibuthe).

Ukube izikulufu zaziseziningi zazizohlohla ikhoyili ye-Magnabend futhi uma bezimfishane-ke bekuyoba nobude bentambo obunganele, okusho ukuthi izintambo zazingase zikhumule lapho izikulufi zishiswa ukuze ziqine (39 Nm).

I-Mounting Block yama-M10 Bolts:

Senze ukuhlolwa okuthile lapho izimbobo zamabhlokhi ezifakwayo zakhuliswa ukuze zamukele amabhawodi e-M10.Lawa mabhawodi amakhudlwana angakwazi ukushibilika abe yi-tension ephakeme (77 Nm) futhi lokhu, kuhlanganiswe nokusebenzisa i-Loctite #680 ngaphansi kwebhlokhi ekhuphukayo, kubangele ukungqubuzana okwanele ukuvimbela ukushibilika kwebhlokhi efakwayo yomshini ojwayelekile we-Magnabend (okulinganiselwe ukugoba. kuze kufike ku-1.6mm insimbi).

Kodwa-ke lo mklamo udinga ukucolisiswa nokuhlolwa okwengeziwe.

Umdwebo ongezansi ubonisa ihinge efakwe emzimbeni kazibuthe ngamabhawodi angu-3 x M10:

Uma noma yimuphi umkhiqizi angathanda imininingwane eyengeziwe mayelana nehinji eboshwe ngokugcwele ngicela ungithinte.

Isikhathi sokuthumela: Oct-12-2022