Abantu bavame ukungicela ukuthi ngihlole izibalo zabo zemiklamo yekhoyili ethi "Magnabend".Lokhu kungenze ngaqhamuka naleli khasi lewebhu elivumela ukubalwa okuzenzakalelayo kwenziwe uma sekufakwe idatha yekhoyili.

Ngibonga kakhulu kumlingani wami, uTony Grainger, ngohlelo lwe-JavaScript owenza izibalo kuleli khasi.

UHLELO LWE-COIL CALULATOR

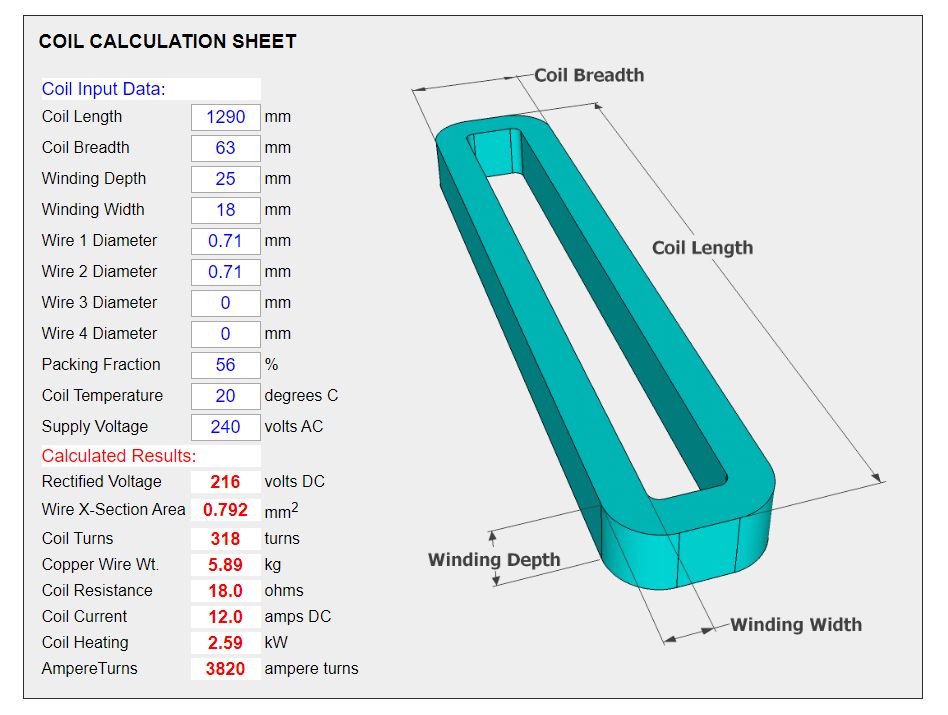

Ishidi lokubala elingezansi laliklanyelwe amakhoyili e-"Magnabend" kodwa lizosebenzela noma iyiphi ikhoyili kazibuthe esebenza kuvolthi elungisiwe (DC).

Ukusebenzisa iphepha lokubala vele uchofoze kuzindawo ze-Coil Input Data bese uthayipha ubukhulu bekhoyili yakho nobukhulu bezintambo.

Uhlelo lubuyekeza isigaba Semiphumela Ebaliwe njalo uma ushaya u-ENTER noma uchofoza kwenye indawo yokufaka.

Lokhu kwenza ukuthi kusheshe kakhulu futhi kube lula ukuhlola idizayini yekhoyili noma ukuhlola idizayini entsha yekhoyili.

Izinombolo ezigcwaliswe ngaphambilini ezinkundleni zedatha yokufaka ziyisibonelo nje futhi ziyizinombolo ezijwayelekile zefolda ye-1250E Magnabend.

Shintsha izinombolo zesibonelo ngedatha yakho yekhoyili.Izinombolo zesibonelo zizobuyela eshidini uma uvuselela ikhasi.

(Uma ufisa ukulondoloza idatha yakho, Gcina noma Shicilela ikhasi ngaphambi kokulivuselela).

Inqubo Yedizayini Yekhoyili Ephakanyisiwe:

Faka izilinganiso zekhoyili oyihlosile, kanye ne-voltage oyihlosile.(Isibonelo 110, 220, 240, 380, 415 Volts AC)

Setha Izintambo 2, 3 kanye no-4 zibe ziro bese uqagela inani lobubanzi be-Wire1 futhi uqaphele ukuthi mingaki imiphumela ye-AmpereTurns.

Lungisa ububanzi be-Wire1 kuze kube yilapho i-AmpereTurns oyihlosile isifinyelelwa, isho cishe ama-AmpereTurns angu-3,500 kuya kwangu-4,000.

Okunye ungasetha i-Wire1 ibe usayizi othandwayo bese ulungisa i-Wire2 ukuze ufinyelele okuhlosiwe, noma usethe kokubili i-Wire1 ne-Wire2 kumasayizi ancanyelwayo bese ulungisa i-Wire3 ukuze ufinyelele okuhlosiwe njll.

Bheka manje I-Coil Heating (i-power dissipation)*.Uma iphezulu kakhulu (yisho ngaphezu kuka-2 kW imitha yobude bekhoyili) kuzomele i-AmpereTurns yehliswe.Kungenjalo kungeza amajika amaningi ekhoyili ukuze kunciphe amandla amanje.Uhlelo lolu luzavele lwengeze amajika amanengi nxa ukhulisa ububanzi kumbe ukujula kwekhoyili, kumbe nxa ukhulisa iPacking Fraction.

Okokugcina thintana nethebula lamageji ezintambo ajwayelekile bese ukhetha intambo, noma izintambo, ezinendawo ehlangene yezingxenye ezilinganayo elingana nenani elibalwe esinyathelweni sesi-3.

* Qaphela ukuthi ukuchithwa kwamandla kuzwela kakhulu ku-AmpereTurns.Kungumphumela womthetho oyisikwele.Isibonelo uma uphinda kabili i-AmpereTurns (ngaphandle kokwandisa indawo ejikajikayo) khona-ke ukuchithwa kwamandla kuzokwenyuka izikhathi ezi-4!

I-AmpereTurns eyengeziwe ibiza izintambo ezijiyile (noma izintambo), futhi intambo ewugqinsi isho ukuchithwa kwamandla amanje nangaphezulu ngaphandle kwalapho inani lokujika lingandiswa ukuze linxephezele.Futhi ukujika okwengeziwe kusho ikhoyili enkulu kanye/noma Isiqephu Esingcono Sokupakisha.

Lolu hlelo Lokubalwa Kwekhoyili likuvumela ukuthi ulinge kalula zonke lezo zici.

AMANOTHI:

(1) Osayizi bezintambo

Uhlelo luhlinzeka ngezintambo ezifika kwezi-4 kukhoyili.Uma ufaka i-diameter yentambo engaphezu kweyodwa uhlelo luzothatha ngokuthi zonke izintambo zizohlanganiswa njengokungathi ziwucingo olulodwa futhi zihlanganiswe ndawonye ekuqaleni nasekupheleni kokujika.(Lokho izintambo zihambisana ngogesi).

(Ngezintambo ezi-2 lokhu kubizwa ngokuthi i-bifilar winding, noma izintambo ezi-3 ze-trifilar winding).

(2) I-Packing Fraction, ngezinye izikhathi ebizwa ngokuthi i-fill factor, iveza iphesenti lesikhala esimazombezombe esithathwe ucingo lwethusi.Kuthintwa ukuma kocingo (imvamisa iyindilinga), ukushuba kokufakwa ocingweni, ukujiya kongqimba lwekhoyili yangaphandle (imvamisa iphepha likagesi), kanye nendlela yokusonteka.Indlela yokusonta ingabandakanya i-jumble winding (ebuye ibizwe ngokuthi i-wild winding) kanye nama-layer winding.

Kukhoyili enenxeba ingxenye yokupakisha ngokuvamile izoba ku-55% kuya ku-60%.

(3) Amandla ekhoyili aphuma ezinambeni zesibonelo esezigcwaliswe ngaphambilini (bheka ngenhla) angu-2.6 kW.Lesi sibalo singase sibonakale siphezulu kodwa umshini weMagnabend ukalelwe umjikelezo wemisebenzi ocishe ube ngu-25%.Ngakho-ke ezicini eziningi kunengqondo kakhulu ukucabanga ngesilinganiso sokuchithwa kwamandla okuphakathi, okuye ngokuthi umshini usetshenziswa kanjani, kuzoba ingxenye yesine kuphela yaleso sibalo, ngokujwayelekile ngisho nangaphansi.

Uma uhlela ukusuka ekuqaleni kusho ukuthi ukuchithwa kwamandla kuyingxenye yokungenisa okufanele icatshangelwe;uma iphakeme kakhulu ikhoyili izoshisa kakhulu futhi ingase yonakale.

Imishini ye-Magnabend yaklanywa enokushabalalisa amandla okungaba ngu-2kW imitha yobude.Ngomjikelezo womsebenzi ongu-25% lokhu kuhumusha cishe ku-500W imitha yobude.

Ukuthi uzibuthe uzoshisa kangakanani kuncike ezintweni eziningi ngaphezu komjikelezo womsebenzi.Okokuqala inertia ezishisayo zikazibuthe, nanoma yini ethintana nayo, (ngokwesibonelo isitendi) kusho ukuthi ukuzifudumeza ngokwakho kuzohamba kancane.Ngokuhamba kwesikhathi izinga lokushisa likazibuthe lizothonywa izinga lokushisa elizungezile, indawo engaphezulu kazibuthe ngisho nangamuphi umbala opendwe!(Isibonelo umbala omnyama ukhipha ukushisa kangcono kunombala osiliva).

Futhi, sicabanga ukuthi uzibuthe uyingxenye yomshini we-"Magnabend", izinto zokusebenza ezigotshwayo zizomunca ukushisa ngenkathi ziboshelwe kuzibuthe futhi ngaleyo ndlela zizothwala ukushisa okuthile.Kunoma yikuphi umazibuthe kufanele uvikelwe idivayisi yohambo olushisayo.

(4) Qaphela ukuthi lolu hlelo lukuvumela ukuthi ufake izinga lokushisa ngekhoyili futhi ngaleyo ndlela ungabona umphumela wawo ekuqineni kwekhoyili kanye namanje.Ngenxa yokuthi intambo eshisayo inokumelana okuphakeme bese iphumela ekuncipheni kwekhoyili yamanje futhi ngenxa yalokho iphinde inciphise amandla kazibuthe (AmpereTurns).Umphumela ubaluleke kakhulu.

(5) Uhlelo luthatha ngokuthi ikhoyili ilinyazwe ngocingo lwethusi, okuwuhlobo lwentambo olusebenziseka kakhulu lwekhoyili kazibuthe.

Intambo ye-aluminum nayo iyinto engenzeka, kodwa i-aluminiyamu inokumelana okuphakeme kunethusi (imitha engu-2.65 ohm uma iqhathaniswa no-1.72 yethusi) okuholela ekwakhiweni okusebenza kahle kakhulu.Uma udinga izibalo ze-aluminium wire sicela uxhumane nami.

(6) Uma uklama ikhoyili yefolda yensimbi yeshidi le-"Magnabend", futhi uma umzimba kazibuthe ungusayizi wesigaba esiphambanayo esijwayelekile (yithi 100 x 50mm) cishe kufanele uhlose amandla kazibuthe (AmpereTurns) azungeze. 3,500 kuya ku-4,000 ama-ampere amajika.Lesi sibalo asizimele kubude bangempela bomshini.Imishini emide izodinga ukusebenzisa izintambo ezinkulu (noma izintambo eziningi) ukuze ifinyelele lelo nani le-AmpereTurns.

Ukujika kwe-ampere okwengeziwe kungaba ngcono, ikakhulukazi uma ufuna ukubopha izinto ezingezona uzibuthe njenge-aluminium.

Kodwa-ke, ngosayizi ojwayelekile ozibuthe nokuqina kwezigxobo, ukuphenduka kwe-ampere okwengeziwe kungatholwa kuphela ngezindleko zamanje eziphezulu futhi ngaleyo ndlela ukuchithwa kwamandla aphezulu kanye nomphumela okhulayo wokushisisa kuzibuthe.Lokho kungase kube KULUNGILE uma umjikelezo wemisebenzi ephansi wamukeleka ngaphandle kwalokho kudingeka isikhala esimazombezombe esikhudlwana ukuze kufakwe amajika amaningi, futhi lokho kusho uzibuthe omkhulu (noma izigxobo ezincanyana).

(7) Uma uklama, ake sithi, i-chuck kazibuthe khona-ke kuzodingeka umjikelezo womsebenzi ophezulu kakhulu.(Ngokuya ngesicelo lapho-ke mhlawumbe umjikelezo womsebenzi we-100% ungase udingeke).Uma kunjalo ungasebenzisa ucingo oluncanyana futhi mhlawumbe udizayine amandla kazibuthe okuthi amajika ayi-1,000 ampere.

Amanothi angenhla awokunikeza nje umbono wokuthi yini engenziwa ngalolu hlelo lokubala lwamakhoyili oluguquguqukayo.

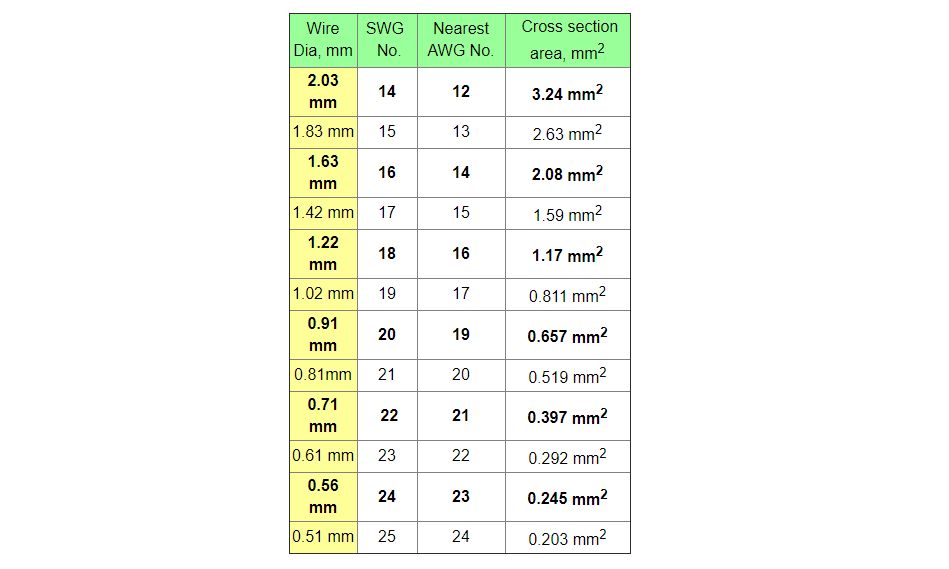

Ama-Standard Wire Gauges:

Ngokomlando amasayizi ezintambo ayekalwa kwelinye lamasistimu amabili:

I-Standard Wire Gauge (SWG) noma i-American Wire Gauge (AWG)

Ngeshwa izinombolo zegeji zalawa mazinga womabili azihambelani futhi lokhu kuholele ekudidekeni.

Namuhla kungcono kakhulu ukuziba lezo zindinganiso ezindala futhi uvele ubhekisele ocingweni ngobubanzi balo ngamamilimitha.

Nali itafula lamasayizi elizohlanganisa noma iyiphi intambo okungenzeka idingelwe ikhoyili kazibuthe.

Osayizi bezintambo ababhalwe ngokugqamile bangosayizi abavame ukugcwala ngakho-ke kungcono ukhethe oyedwa walabo.

Isibonelo, i-Badger Wire, i-NSW, i-Australia igcina osayizi abalandelayo ocingweni lwethusi oluhlanganisiwe:

0.56, 0.71, 0.91, 1.22, 1.63, 2.03, 2.6, 3.2 mm .

Ngicela ungithinte nganoma yimiphi imibuzo noma ukuphawula.

Isikhathi sokuthumela: Oct-12-2022