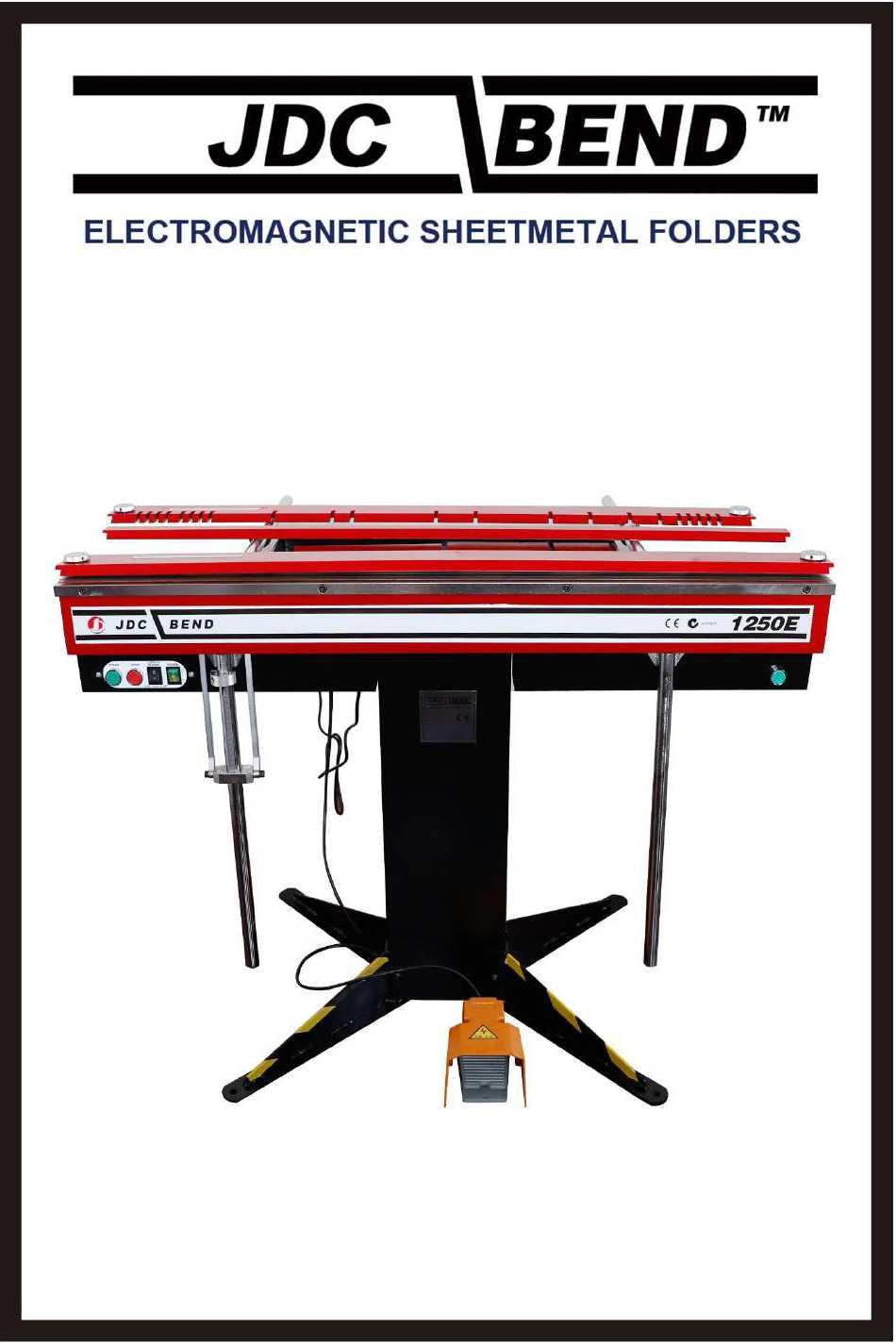

I-JDCELECTROMAGNETIC SHEETMETAL FOLDERS

I-JDC GOBA • IMANUWALI YOMSEBENZISI

okwe

AMAmodeli 650E, 1000E& 1250E

Okuqukethwe

ISINGENISO

UMHLANGANO

IMICIMBI

ISHIDI LOKUHLOLA

UKUSEBENZISA I-JDCBEND

UKUSEBENZA OKUYISISEKO

I-POWER SHEAR ACCESSORY

ULEBE OLONGWE (HEM)

I-EDGE EGIJIKIWE

UKWENZA ISIQEPHU SOKUHLOLA

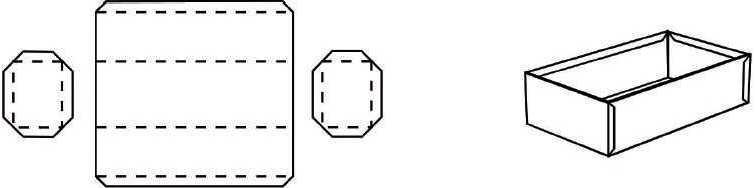

AMABHOKSI (AMA-CLAMPBARS AMAFUSHA)

AMATHLEY (AMA-CLAMPBARS AMA-SLOTTED)

UKUSEBENZISA IZINDABA

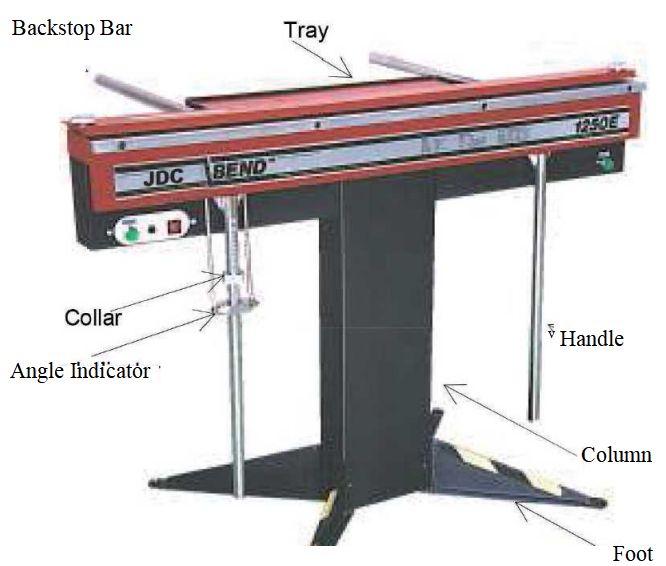

I-JDC GOBA-ISINGENISO

I-Jdcbendumshini wokugoba i-sheetmetal ungumshini osebenziseka ngezindlela eziningi futhi kulula ukuwusebenzisa ukugoba zonke izinhlobo ze-sheetmetal njenge-aluminium, i-cop-per, insimbi, nensimbi engagqwali.

I-electromagnetic clamping systeminikeza inkululeko eyengeziwe yokwenza ucezu lokusebenza lube yizimo eziyinkimbinkimbi.Kulula ukwenza ama-chan nel ajulile kakhulu, izingxenye ezivaliwe, namabhokisi ajulile anzima noma angenakwenzeka emshinini ovamile.

I-hinging system eyingqayiziveleesetshenziselwa ugongolo olugobayo luhlinzeka ngomshini ovuleke ngokuphelele ngaleyo ndlela andisa kakhulu ukuguquguquka kwawo.Idizayini yesitendi sekholomu eyodwa iphinde inikele ekusebenzisaneni ngezindlela eziningi komshini ngokunikeza umphumela "we-free-arm" ekugcineni komshini.

Ukusebenziseka kalulakugeleza kusukela ekulawuleni komunwe wokugoqa nokuqaqa, ukukhululeka nokunemba kokuqondanisa i-goba, nokulungiswa okuzenzakalelayo kokujiya kwe-sheetmetal.

Ukuhlangana kwezandla ezimbiliinikeza ukuphepha komqhubi.

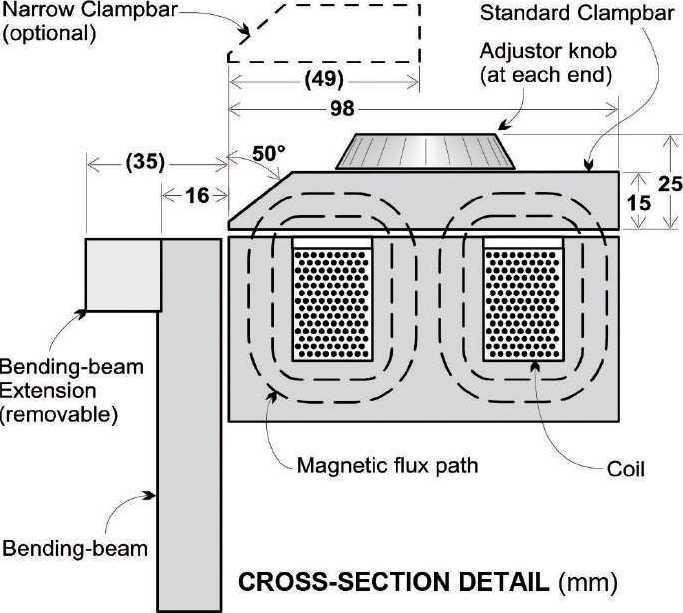

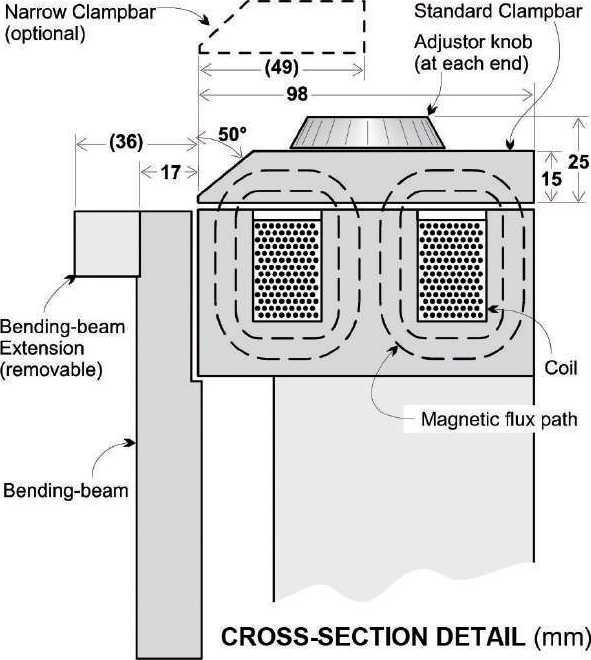

Ngokuyisisekeloukusetshenziswa kwe-clamping kazibuthe kusho ukuthi imithwalo egobayo ithathwa khona lapho ikhiqizwa khona;amabutho akudingeki adluliselwe ezakhiweni zokusekela ekugcineni komshini.Lokhu kusho ukuthi ilungu elibambayo alidingi noma iyiphi inqwaba yesakhiwo ngakho-ke lingenziwa liminyene kakhulu futhi lingavimbeli.(Ubukhulu be-clampbar bunqunywa kuphela isidingo sayo sokuthwala i-flux kazibuthe eyanele hhayi ngokucatshangelwa kwesakhiwo nhlobo).

Amahinge ahlanganisiwe angenawo maphakathiathuthukiswe ikakhulukazi i-Jdcbend, futhi asakazwa ngobude be-beam egobayo futhi ngaleyo ndlela, njenge-clampbar, athathe imithwalo egoba eduze nalapho ekhiqizwa khona.

Umthelela ohlangene wei-clamping magnetickanye nesipesheliamahinge angenandawokusho ukuthi i-Jdcbend iwumshini ohlangene kakhulu, owonga isikhala, onesilinganiso esiphakeme kakhulu samandla nesisindo.

Ukuze uthole okuningi emshinini wakho,sicela ufunde leli bhukwana, ikakhulukazi isigaba esinesihloko esithi UKUSEBENZISA I-JDCBEND.Sicela uphinde ubuyisele UKUBHALISA KWE-WAR-RANTY njengoba lokhu kuzokwenza lula noma yiziphi izimangalo ngaphansi kwewaranti futhi futhi kunikeza umkhiqizi irekhodi lekheli lakho elisiza ukugcina amakhasimende enolwazi nganoma yikuphi ukuthuthukiswa okungase kuzuze wona.

UMHLANGANO...

IMIYALELO YOMHLANGANO

1. Khipha ikholomu nezinyawo bese uthola iphakethe lezibophelelo kanye nokhiye ongu-6 mm Allen.

2.Namathisela izinyawo kukholamu.Ipheya yezinyawo ezinetheyiphu yokuphepha emnyama nephuzi kufanele ibheke phambili ukusuka kukholamu.(Ubuso bangaphambili bekholomu wuhlangothi olungahlangani nalo.)

Sebenzisa izikulufu zekhanda lezinkinobho ze-MIO x 16 ukuze unamathisele izinyawo.

3.Amamodeli 650E kanye ne-1000E: Namathisela iplate yezinyawo ngaphansi kwamathiphu ezinyawo zangaphambili.Sebenzisa izikulufu ezimbili ze-MIO x 16 cap-head ezinamawasha.Ukuqondanisa kwezimbobo zezikulufu kuzokwenziwa kube lula uma izikulufu zokukhweza unyawo zishiywa zixega kuze kube ngemva kokufakwa kweplate lezinyawo.Izikulufu ze-cap-head M8 x 20 ezinyaweni ezingemuva zingase zilungiswe ukuze zilingane nomshini futhi zifanele noma yikuphi ukungalingani phansi.

Idatha ye-1250E: Iplate lezinyawo alinikezwanga nalo mshini;kumele iboshelwe phansi ezinyaweni zangaphambili.

4.Ngosizo lomsizi beka ngokucophelela umshini we-Jdcbend esitendini futhi uwuvikele ngezikulufu ze-cap-head M8 x 16.

Amamodeli 650E & 1000E: Qinisekisa ukuthi uqondisa izintambo nesixhumi phansi kukholamu njengoba umshini wehliswa endaweni yokumisa.

5.Amamodeli 650E & 1000E: Khipha iphaneli yokufinyelela kagesi yangemuva bese uxhuma isixhumi samaphini angu-3.Lokhu kuxhuma uzibuthe kagesi emzimbeni womshini neyunithi kagesi kukholamu.Faka esikhundleni iphaneli.Idatha ye-1250E: Bophela isiqeshana sekhebula elikhulu ngemuva kwekholomu ngesikulufu se-pan-head M6 x 10.

6.Imodeli 650E: Joyina amahhafu amabili ethreyi usebenzisa izikulufu zepani ze-M6 namantongomane.Namathisela ithreyi (ngocansi lwenjoloba) ngemuva komshini usebenzisa izikulufu ezimbili ze-cap-head M8 x 12.Faka ama-backstop amaslayidi amabili ezinhlangothini zethreyi.

Amamodeli 1000E kanye 1250E: Namathisela amabha amabili e-backstop ngemuva komshini usebenzisa izikulufi ezimbili ze-M8 x 16 zebha ngayinye.Namathisela ithreyi (ngocansi lwerabha) ngemuva komshini usebenzisa izikulufu ezintathu ze-cap-head M8 x 16.Faka ikhola yesitobhi kubha ngayinye yangemuva.

7.Namathisela isibambo nge-M8 x 16 cap-head screws.

Amamodeli 650E kanye 1000E: Isibambo kufanele sehliselwe phansi nge-engeli ekhombisa indandatho ngaphambi kokunamathisela isibambo.

Idatha ye-1250E: Isibambo esinesikali se-engeli kufanele sifakwe ohlangothini lwesobunxele, bese kuthi ikhola yokumisa ishelele kuso bese iboshelwa phezulu eduze nangaphezulu kwesibambo.

8.Imodeli 1250E: Swayiphela i-beam egobayo iye phezulu idlule ku-180°.Khipha i-

gle inkomba bese udlulisa Isilayidi Inkomba phezu kwesibambo sobunxele.Khipha izikulufi ezimbili ze-cap-head M8 ukusuka ku-anchor-block yenkomba eboshelwe kusisekelo somshini eduze nesibambo sangakwesokunxele.Namathisela Izingalo Zenkomba ku-anchor-block bese uqinisa zombili izikulufi zekhanda lekhanda le-M8 ngesandla bese, usebenzisa ukhiye ongu-6 mm Allen, uqinise zombili izikulufu ziqine kakhulu.

Qaphela:Umshini kungenzeka UNGAVULI uma lezi zikulufi zingaqinile.

9. Ukusebenzisa isincibilikisi esikloriniwe (noma uphethiloli) hlanza ukunamathela okucacile okufana nengcina endaweni yokusebenza yomshini.

10.Beka ama-clamp bar amafushane ethreyini kanye ne-clamp bar yobude obugcwele phezu komshini namabhola awo okuthola indawo ahlezi ezinkundleni ebusweni obungaphezulu bomshini.

11.Xhuma esitokisini samandla bese UVULA iswishi eyinhloko.Umshini manje usulungile

ukuze usebenze - sicela ubhekisele kokuthi ”BASIC OPERATION1' kule ncwadi.

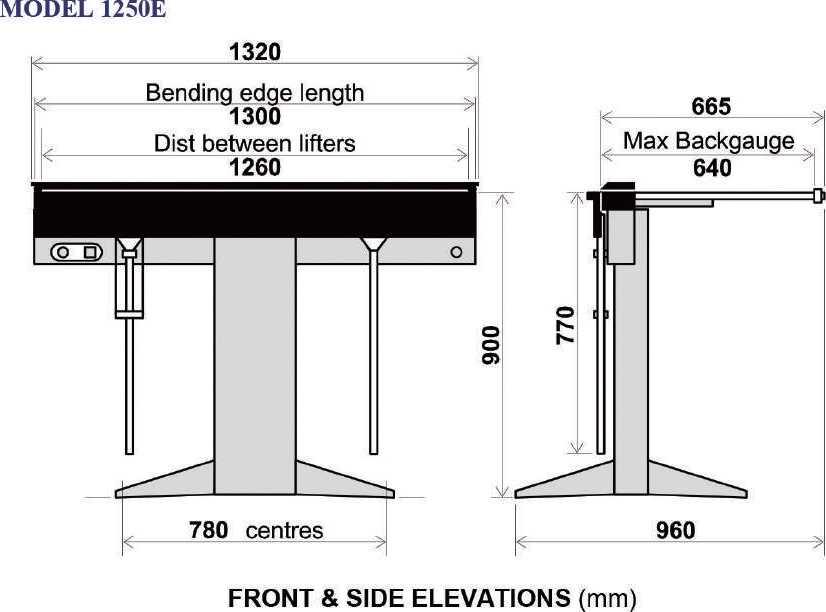

| Idatha ye-650E | 625 mm x 1.6 mm | (2ftx 16g) | 72 kg |

| Imodeli 1000E | 1000 mm x 1.6 mm | (3ft x 16g) | akukho kg |

| Idatha ye-1250E | 1250 mm x 1.6 mm | (4ftx 16g) | 150 kg |

AMANDLA OKUBAMBA

Amandla aphelele ane-clamp-bar ejwayelekile yobude obugcwele:

AMANDLA EZIZIWO

Isisindo Somshini

| Idatha ye-650E | 4.5 amathani |

| Imodeli 1000E | 6 amathani |

| Idatha ye-1250E | 3 amathani |

AMAGEZI

Isigaba esingu-1, 220/240 V AC

Okwamanje:

| Idatha ye-650E | 4 amp |

| Imodeli 1000E | 6 amp |

| Idatha ye-1250E | 8 amp |

Umjikelezo Womsebenzi:30%

Ukuvikelwa: Ukusika kwe-thermal, 70°C

Ukulawula:Inkinobho yokuqala ...amandla okugoqa ngaphambili

Igoba i-microswitch ye-beam...i-clamping egcwele

I-Interlock...inkinobho yokuqala kanye ne-beam egobayo kufanele kudwetshwe ngokulandelana okulungile okugqagqene ukuze kuqaliswe amandla okugoqa agcwele.

AMAHINGA

Idizayini ekhethekile engenasikhungo yokuhlinzeka ngomshini ovuleke ngokuphelele.

I-engeli yokujikeleza: 180°

UKUGOBA UBUKIMO

IKHONO LOKUGOBA

| IZINTO (isivuno/ingcindezi yokugcina) | UBUDILI |

| Insimbi ethambile (250/320 MPa) | 1.6 mm |

| 1.2 mm | |

| 1.0 mm | |

| I-AluminiumGrade 5005 H34(140/160 MPa) | 1.6 mm |

| 1.2 mm | |

| 1.0 mm | |

| Insimbi engagqwali Amabanga 304,316 (210/600 MPa) | 1.0 mm |

| 0.9 mm | |

| 0.8 mm |

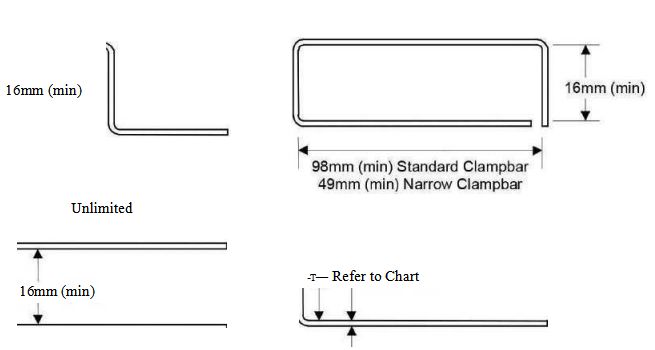

| IZILEBE UBUNZI | GOBA UMSAKAZI |

| (okuncane) | (okujwayelekile) |

| 30 mm* | 3.5 mm |

| 15 mm | 2.2 mm |

| 10 mm | 1.5 mm |

| 30 mm* | 1.8 mm |

| 15 mm | 1.2 mm |

| 10 mm | 1.0 mm |

| 30 mm* | 3.5 mm |

| 15 mm | 3.0 mm |

| 10 mm | 1.8 mm |

(Lapho usebenzisa i-clamp-bar ejwayelekile yobude obugcwele ukugoba ucezu lokusebenza olugcwele)

* Ngebha enwetshiwe efakwe kugongolo olugobayo.

ISETHI YE-CLAMP-BAR EMFUSHANE

Ubude: Imodeli 650E: 25, 38, 52, 70, 140, 280 mm

Amamodeli 1000E & 1250E: 25, 38, 52, 70, 140, 280, 597 mm

Bonke osayizi (ngaphandle kuka-597 mm) bangase baxhunywe ndawonye ukuze bakhe unqenqema olugobile phakathi kuka-25 mm wanoma yibuphi ubude obufiswayo obufika ku-575 mm.

I-SLOTTED CLAMPBAR

Uma ihlinzekwa, isethi ekhethekile yama-slots angu-8 mm ububanzi ihlinzeka ngokwakha bonke osayizi bethreyi ebangeni eliboniswe ngezansi:

* Ukuze uthole amathreyi ajulile sebenzisa isethi ye-Short Clamp-bar.

| INDLELA | UBUDE BETHREY | MAX.UKUJULA KWETRAY |

| 650E | 15 kuya ku-635 mm | 40 mm* |

| 1000E | Imizuzu eyi-15 kuye kwengama-1015 | 40 mm* |

| 1250E | 15 kuya ku-1265 mm | 40inm* |

AMAmodeli 650E/ 1000E

AMABUKU ANGAPHAMBI KANYE NEMAceleni (mm)

INDLELA INOMBOLO YOSIZI. DATE

IZIXHUMANO ZOMHLABA

Linganisa ukumelana kusuka kuma-mains plug Earth pin ukuya emzimbeni kazibuthe .... ohm

UKWEHLUKANA KAgesi

Megger kusuka kukhoyili kuya emzimbeni kazibuthe

IZIVIVINYO ZAMAVOTI OKUPHUMA OKUMN/MAX

Ku-260v: I-Pre-clamp.... i-full-clamp.... khulula

Ku-200v: I-Pre-clamp.... khulula

I-Pre-clamp.... i-full-clamp.... khulula

UKUHLANGANYELA KWE-INTERLOCK

Uma amandla avuliwe, donsa HANDLE, bese ucindezela inkinobho ethi QALA.

Hlola ukuthi umshini AWUVUMI

VULA/VIMA AMA-ANGLES

Ukunyakaza kwe-Beam yokugoba ukuze kusebenze i-clamping egcwele,

kukalwa ngaphansi kogongolo olugobayo.(4 mm ukuya ku-6 mm) mm

Hlehlisa ukunyakaza emshinini wokucisha.Kala emuva

kusuka ku-90 °.(Kufanele ibe phakathi kwebanga elingu-15° + 5° ) deg

I-ANGLE SCALE

Ukufunda emaphethelweni eNkomba lapho ugongolo lusethiwe

ukuya ku-90° ngesikwele sikanjiniyela.(imizuzu engu-89°, ubuningi 91°) deg

UMZIMBA KAZIBUTHO

Ukuqina kwendawo engaphezulu, eduze kwesigxobo esingaphambili

(ukuchezuka okukhulu = 0.5 mm)Imm

Ukucaba kwendawo engaphezulu, ngaphesheya kwezigxobo

(ukuchezuka okukhulu = 0.1 mm) mm

UKUGOBA UGOVU

Ukuqonda kwendawo yokusebenza (ukuchezuka okukhulu =0.25 mm)

Ukuqondanisa kwebha yokunweba (ukuchezuka okukhulu = 0.25 mm)[Qaphela:Hlola ubuqotho ngokunemba okuqondile.]

I-CLAMPBAR EYINHLOKO

Ukuqondile komphetho ogobayo (ukuchezuka okukhulu = 0.25 mm) Ubude be-lift (namabhola okuphakamisa emiseleni) (min 3 mm) Ingabe amabhola okuphakamisa angakwazi ukucindezelwa ashibilike phezulu.n1nkanye ne-beam yokugoba ku-90 °

unqenqema lokugobangokuhambisanakuye, futhingi mmkusuka, i-beam Nge-beam egobayo ku-90 °, i-clampbar ingalungiswa phambilithintafuthi emuva nge2 mm

AMAHINGA

Bheka ukugcotshwa ku-shafts.kanye namabhulokhi womkhakha

Hlola ukuthi amahinge azungeza ku-180° ngokukhululeka nangokushelela

Hlola ihingeizikhonkwanedo hhayizungeza.futhi zitholakala

Ingabe amantongomane esikulufa asele akhiyiwe?

UKUGOBA TEST

(Isilinganiso esiphezulu sokugoba ukuya ku-90°, ku-voltage encane yokuhlinzeka.)

Ukujiya kocezu lwensimbi yokuhlola

Ububanzi bomlomo

mm, Gobisa ubude

mm, irediyasi yokugoba

Ukufana kwe-engeli yokugoba (ukuchezuka okukhulu = 2°)

AMALABELS

Hlola ukucaca, ukunamathela emshinini nokuqondanisa okufanele.

I-Nameplate nenombolo ye-serial

Izixwayiso zikagesi

Isexwayiso se-Clampbar

Shintsha ukulebula

Itheyiphu yokuphepha emilenzeni yangaphambili

QEDA

Hlola ukuhlanzeka, ukukhululeka ekugqwaleni, amabala njll

IZIGENES

Kuhlanganisiwe Kwahlolwa .

Ukuhlolwa kwe-QA

UKUSEBENZA OKUYISISEKO

ISEXWAYISO

Ifolda yensimbi yeshidi le-Jdc bend ingasebenzisa amandla okubamba aphelele amathani amaningana (bona IMIBHALO).Ifakwe i-interlock yezandla ezimbili ukusiza ukuqinisekisa ukuthi iminwe ayikwazi ukubanjwa ingaqondile ngaphansi kwe-clampbar lapho kufakwa i-electro-magnetic clamping.

Nokho,kubaluleke kakhulu ukuthi oyedwa kuphela osebenzisa umshini ngesikhathi.Kungase kube yingozi ukuthi umuntu oyedwa afake ucezu lokusebenza futhi abambe izinsimbi zokubopha kuyilapho omunye eqhuba amaswishi !

UKUGOBA OKUJWAYELEKILE

Qinisekisa ukuthi amandla AVULIWE endaweni yokukhipha amandla futhi i-clampbar yobude obugcwele ibekwe emshinini namabhola awo okuphakamisayo ahlezi ezindaweni ezitholakala kuzo ekugcineni ngakunye.

1.Lungisa ukujiya kwe-workpiecengokuzungezisa izilungisi ze-eccentric ekugcineni kwe-clampbar.Phakamisa i-beam egobayo uye endaweni engu-90° futhi uhlole ukuthi iyahambisana yini nonqenqema lwe-clampbar - uma kunesidingo, lungisa kabusha iziphakamisi ze-eccentric.

(Ukuze uthole imiphumela emihle igebe phakathi konqenqema lwe-clampbar kanye nengaphezulu le-beam egotshwayo kufanele lisethwe libe likhulu kancane kunokuqina kwensimbi okumele kugotshwe.)

2.Faka i-workpiecebese utshekisa unqenqema lwangaphambili lwe-clampbar phansi bese uqondanisa umugqa wokugoba onqenqemeni olugobayo.

3.Cindezela bese ubamba inkinobho ethi QALA.Lokhu kusebenza ku-pre-clamping.

5.I-beam egobayo ingase ihlehliswe cishe ngo-10 ° kuya ku-15 ° ukuze kukhishwe ingcindezi ku-workpiece ukuze kuhlolwe i-engeli yokugoba.Ukuhlehla ngaphezu kuka-15° kucisha umshini ngokuzenzakalelayo futhi kudedele ucezu lomsebenzi.

ISEXWAYISO

- Ukuze ugweme ingozi yokulimaza unqenqema olugobile lwe-clampbar noma ukuboleka indawo engaphezulu yomzimba kazibuthe,ungafaki izinto ezincane ngaphansi kwe-clampbar.Ubude obuncane bokugoba obunconyiwe kusetshenziswa i-clampbar evamile ngu-15 mm, ngaphandle uma ucezu lomsebenzi luncane kakhulu noma luthambile.

- Amandla okubamba uzibuthe mancane uma kushisa.Ngakho-ke ukuze uthole ukusebenza okuhle kakhulusebenzisa i-clamping isikhathi eside kunalokho okudingekileukwenza ukugoba.

AMANDLA SHEAR(Ongakukhetha)

IMIYALELO YOKUSEBENZISA

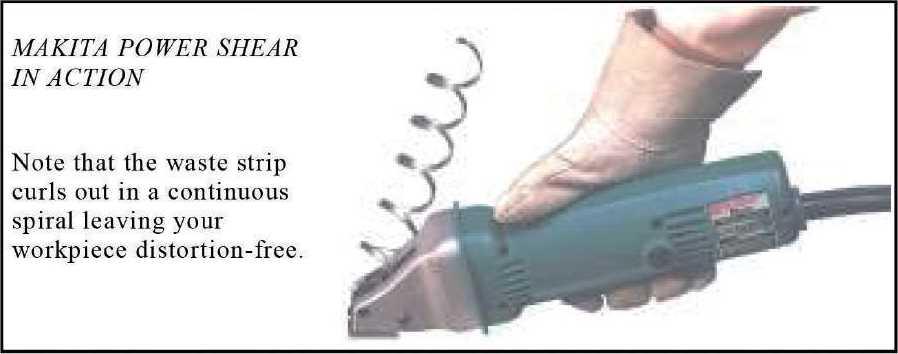

I-shear yamandla (esekelwe ku-Makita Model JS 1660) inikeza indlela yokusika i-sheetmetal ngendlela yokuthi ukuhlanekezela okuncane kakhulu kusele ku-workpiece.Lokhu kungenzeka ngoba ukugunda kususa umucu kadoti, ongaba ngu-4 mm ububanzi, futhi okuningi kokuhlanekezela okukhona ekusheleni insimbi kungena kulo mucu kadoti.Ukuze isetshenziswe nge-Jdcbend i-shear ifakwe umhlahlandlela okhethekile kazibuthe.

I-shear isebenza kahle ngokuhambisana nefolda ye-Jdcbend Sheetmetal;i-Jdcbend ihlinzeka ngazo zombili izindlela zokubamba ucwecwe lokusebenza lulungisiwe ngenkathi lusikwa kanye nendlela yokuqondisa ithuluzi ukuze ukusika okuqonde kakhulu kwenzeke.Ukusikwa kwanoma ibuphi ubude kungaphathwa ngensimbi kuze kufike ku-1.6 mm ubukhulu noma i-aluminium kuze kufike ku-2 mm ubukhulu.

Ukusebenzisa ithuluzi kuqala beka i-workpiece ye-sheetmetal ngaphansi kwe-clampbar ye-Jdcbend futhi uyibeke ukuze umugqa wokusika ube ncamashi.] mmphambi konqenqema Lokugoqa.

Iswishi yokuguqula ebhalwe ukuthi "NORMAL / AUX CLAMP,, izotholakala eduze kweswishi enkulu YOKUVAKA/UKUVALA. Shintshela lokhu endaweni ye-AUX CLAMP ukuze ubambe ucezu lokusebenza luqine.

Misa i-shear ekugcineni kwesandla sokudla se-Jdcbend futhi uqinisekise ukuthi okunamathiselwe komhlahlandlela kazibuthe kubandakanyeka emaphethelweni angaphambili e-Beam egoqayo.Qala i-shear yamandla bese uyisunduza ngokulinganayo kuze kube yilapho ukusika kuqediwe.

Amanothi:

- Ukuze kusebenze kahle i-blade clearance kufanele ilungiswe ukuze ivumelane nogqinsi lwezinto okufanele zisikwe.Sicela ufunde imiyalelo ye-Makita ehlinzekwe ne-JS1660 shear.

- Uma i-Shear ingasiki ngokukhululekile hlola ukuthi izindwani zibukhali yini.

ULEBE OLUGOBILE

UKUSONQA ULEBE (HEM)

Inqubo esetshenziselwa ukusonga izindebe incike ekujikeni kwengcezu yokusebenza futhi ngokwezinga elithile, ngobude nobubanzi bayo.

Ama-Workpieces azacile (kufika ku-0.8 mm)

1.Qhubeka njengokugoba okujwayelekile kodwa uqhubeke nokugoba ngangokunokwenzeka (135°).

2.Khipha i-clampbar bese ushiya ucezu lokusebenza emshinini kodwa uyihambise emuva cishe ngo-10 mm.Manje shwiba ugongolo ukuze ucindezele udebe.(I-clamping ayidingi ukusetshenziswa).[Qaphela: Ungazami ukwenza izindebe eziwumngcingo ezintweni zokusebenza eziwugqinsi].

3.Ngezinto zokusebenza ezizacile, kanye/noma lapho udebe lungeluncane kakhulu, ukwenza isicaba okuphelele kungafinyelelwa ngokulandela ngokucindezela kazibuthe kuphela:

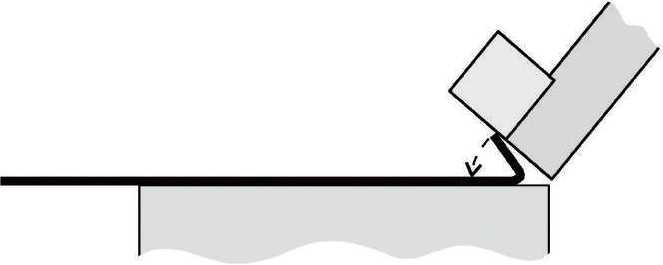

I-EDGE EGIJIKIWE

UKWAKHA UMphetho OGOQILE

Imiphetho egoqiwe yenziwa ngokusonga umsebenzi ozungeze ibha yensimbi eyindilinga noma ucezu lwepayipi elinezindonga eziwugqinsi.

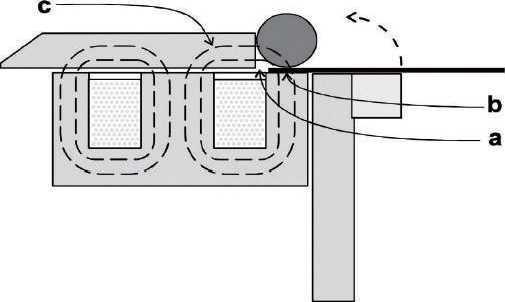

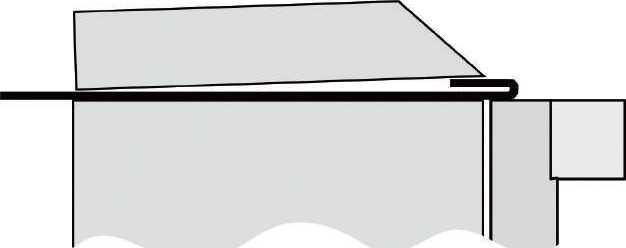

1.Beka ucezu lokusebenza, i-clampbar kanye ne-rolling bar njengoba kukhonjisiwe.

a) Qinisekisa ukuthi i-clampbar ayidluleli isigxobo esingaphambili somshini ku-"a" njengoba lokhu kuzovumela ukuguquguquka kazibuthe ukuthi kudlule umugqa ogoqayo ngakho-ke ukubamba kuzoba buthakathaka kakhulu.

b) Qiniseka ukuthi i-rolling bar ihlezi esigxotsheni sensimbi esingaphambili somshini womshini (“b”) hhayi emuva kakhulu engxenyeni ye-aluminium yendawo.

c) Injongo ye-clanipbar iwukuhlinzeka ngendlela kazibuthe ("c”) eya kubha egoqekayo.

2.Gcoba ucezu lokusebenza ngokusemandleni akho bese ubeka kabusha indawo njengoba kukhonjisiwe.

3.Phinda isinyathelo sesi-2 njengoba kudingeka.

ISIQEPHU SOKUHLOLA

IMIYALELO YOKWAKHA ISIQEPHU SOKUHLOLA

Ukuze ujwayelane nomshini wakho kanye nohlobo lwemisebenzi engenziwa ngawo, kunconywa ukuthi kwakhiwe ucezu lokuhlola njengoba kuchazwe ngezansi:

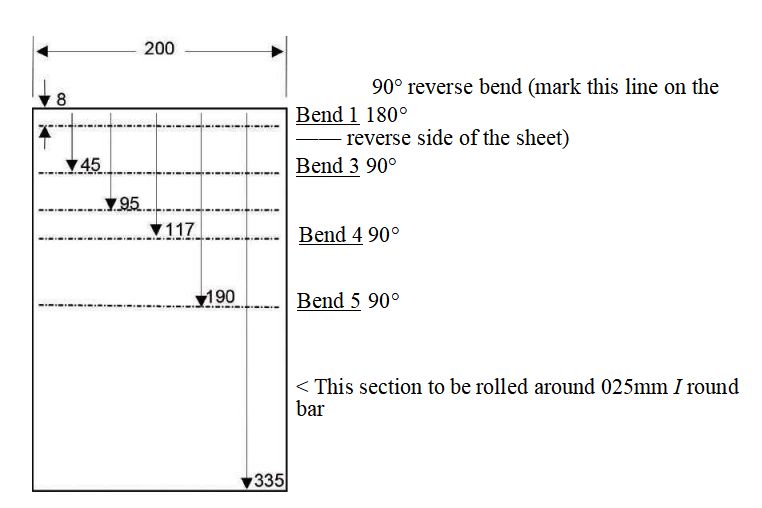

1.Khetha ucezu lwensimbi engu-0.8 mm obukhulu obumnene noma ishidi le-aluminium bese ulisika libe ngu-335 x 200 mm.

2.Maka imigqa eshidini njengoba kukhonjisiwe ngezansi:

3.QondanisaGoba 1bese wenza udebe emaphethelweni e-workpiece.(Bheka

3.QondanisaGoba 1bese wenza udebe emaphethelweni e-workpiece.(Bheka "ULEBE GOGODWE")

4.Phendula ucezu lokuhlola bese ulushelela ngaphansi kwe-clampbar, ushiye unqenqema olugoqiwe lubheke kuwe.Tshekisa i-clampbar phambili bese umugqaBhenda 2.Yenza lokhu kugoba ku-90°.Ucezu lokuhlola manje kufanele lubukeke kanje:

…ISIQEPHU SOKUHLOLA

5.Vula ucezu lokuhlola bese wenzaGobisa 3, Gobisa 4futhiBhenda 5ngakunye kuya ku-90°

6. Ukuze uqedele umumo, ucezu olusele kufanele lugoqwe luzungeze ibha eyindilinga yensimbi engu-25 mm ububanzi.

- Khetha i-clamp-bar engu-280 mm bese uyibeka, ucezu lokuhlola kanye nebha eyindilinga emshinini njengoba kuboniswe ngaphansi kokuthi "ROLLED EDGE" ekuqaleni kwale manuwali.

- Bamba ibha eyindilinga ngendlela ngesandla sokudla bese usebenzisa i-pre clamping ngokucindezela futhi ubambe inkinobho ethi QALA ngesandla sobunxele.Manje sebenzisa isandla sakho sokudla ukuze udonse isibambo njengokungathi wenza ukugoba okuvamile (inkinobho ethi START ingase ikhishwe).Gcoba ucezu lomsebenzi ngokusemandleni akho (cishe ama-90°).Beka kabusha ucezu lokusebenza (njengoba kukhonjisiwe ngaphansi kokuthi "Ukwenza Unqenqema Olugoqiwe") bese usonga futhi.Qhubeka kuze kuvalwe umqulu.

Umumo wokuhlola usuqedile.

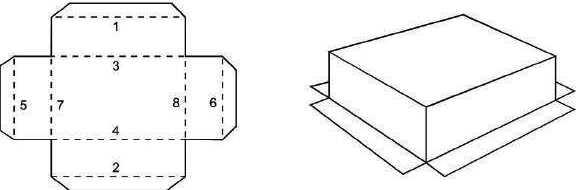

AMABHOKISI...

UKWENZA AMABHOKISI (KUSEBENZISA AMA-CLAMPBARS AMAFUSHANE)

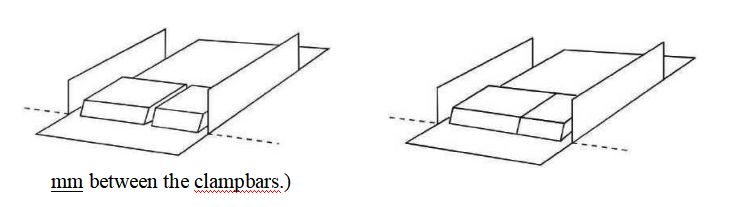

Kunezindlela eziningi zokubeka amabhokisi nezindlela eziningi zokuwagoqa.I-JDCBEND ifaneleka kahle ukwenza amabhokisi, ikakhulukazi ayinkimbinkimbi, ngenxa yokuguquguquka kokusebenzisa ama-clampbars amafushane ukwenza ukugoqa okungavinjwanga ukugoqa kwangaphambilini.

Amabhokisi Angenalutho

1.Yenza ukugoba okubili kokuqala usebenzisa i-clampbar ende njengokugoba okuvamile.

2.Khetha i-clampbar eyodwa noma ngaphezulu amafushane nendawo njengoba kukhonjisiwe.(Akudingekile ukwenza ubude obuqondile njengoba ukugoba kuzothwala izikhala okungenani20 mmphakathi kwama-clampbars.)

Ukuze uthole ukugoba okungafika ku-70 mm ubude, vele ukhethe ucezu lokunamathisela olukhulu kakhulu oluzolingana.Ukuze kube nobude obude kungase kudingeke ukuthi kusetshenziswe izingcezu ezimbalwa zokubopha.Vele ukhethe i-clampbar ende kakhulu ezongena, bese kuba yinde kakhulu ezongena esikhaleni esisele, futhi mhlawumbe neyesithathu, ngaleyo ndlela wenze ubude obudingekayo.

Ukuze ugobe ngokuphindaphindiwe izingcezu zokubopha zingaxhunywa ukuze kwenziwe iyunithi eyodwa enobude obudingekayo.Kungenjalo, uma amabhokisi enezinhlangothi ezingashoni futhi une ai-clampbar efakiwe,khona-ke kungase kusheshe ukwenza amabhokisi ngendlela efanayo namathileyi angashoni.(Bheka isigaba esilandelayo: AMATHILE)

Amabhokisi anezindebe

Amabhokisi anezindebe angenziwa kusetshenziswa isethi evamile yama-clampbar amafushane inqobo nje uma ubukhulu obunye bukhulu kunobubanzi be-clampbar (98 mm).

1.Usebenzisa i-clampbar yobude obugcwele, yakha ubude obugoqiwe ngokuhlakanipha 1, 2, 3, &4.

2.Khetha i-clampbar emfushane (noma okungenzeka kuxhumeke kubili noma kathathu) enobude okungenani obunobubanzi bomlomo obufushane kunobubanzi bebhokisi (ukuze ikhishwe kamuva).Yenza ukugoqa 5, 6, 7 & 8. Ngenkathi wenza ukugoqa 6 & 7, qaphela ukuqondisa ikhona

... AMABHOKISI...

Amabhokisi aneziphetho ezihlukene

Ibhokisi elenziwe ngeziphetho ezihlukene linezinzuzo ezimbalwa:

-igcina impahla uma ibhokisi linezinhlangothi ezijulile,

-akudingi ukufakwa ekhoneni,

-konke ukusika kungenziwa nge-guillotine,

-konke ukugoqa kungenziwa nge-clampbar yobude obugcwele;

kanye nezinye izithiyo:

- kufanele kwakhiwe amafolda amaningi,

-amakhona amaningi kumele ahlanganiswe, futhi

-imiphetho yensimbi eyengeziwe kanye nezixhumi ziboniswa ebhokisini eliqediwe.

Ukwenza lolu hlobo lwebhokisi kuqonde phambili futhi i-clampbar yobude obugcwele ingasetshenziswa kuwo wonke amafolda.

1.Lungiselela izikhala njengoba kukhonjisiwe ngezansi.

2.Qala ngokugoqa okune kucezu lokusebenza olukhulu.

4.Hlanganisa ibhokisi ndawonye.

Amabhokisi ane-flanged anamakhona angenalutho

Amabhokisi anamakhona angenalutho anama-flange angaphandle kulula ukuwenza uma ubude nobubanzi bukhulu kunobubanzi be-clampbar obungu-98 mm.Ukwakhiwa kwamabhokisi anama-flange angaphandle kuhlobene nokwenza IZIGCAWU ZE-TOP-HAT (okuchazwe esigabeni esilandelayo - bona Okuqukethwe).

4.Lungisa isikhala.

5.Usebenzisa i-clampbar yobude obugcwele, phinda ifomu 1, 2, 3 & 4.

6.Faka iflenge ngaphansi kwe-clampbar ukuze wenze ukugoqa okungu-5, bese ugoqa u-6.

7.Usebenzisa izinsimbi ezimfishane ezifanele, qedela ukugoqa 7 & 8.

... AMABHOKISI

Ibhokisi Eliphekiwe elinama-Corner Tabs

Uma wenza ibhokisi elingaphandle eline-flanged ngamathebhu ekhoneni futhi ngaphandle kokusebenzisa izingcezu zokugcina ezihlukene, kubalulekile ukwakha ama-folds ngokulandelana okulungile.

1.Lungisa okungenalutho ngamathebhu ekhona ahlelwe njengoba kukhonjisiwe.

3.Ekugcineni okufanayo kwe-clampbar yobude obugcwele, yenza ukugoqanBn kuya ku-45° kuphela.Yenza lokhu ngokufaka uhlangothi lwebhokisi, esikhundleni sangaphansi kwebhokisi, ngaphansi kwe-clampbar.

4.Kwesinye isiphetho se-clampbar yobude obugcwele, yakha ama-flange agoqekayo "C" kuya ku-90°.

5. Ukusebenzisa ama-clampbar amafushane afanelekile, ukugoqa okuphelelenBnku90.

6.Joyina amakhona.

Khumbula ukuthi emabhokisini ajulile kungase kube ngcono ukwenza ibhokisi elinezicucu ezihlukene zokuphela.

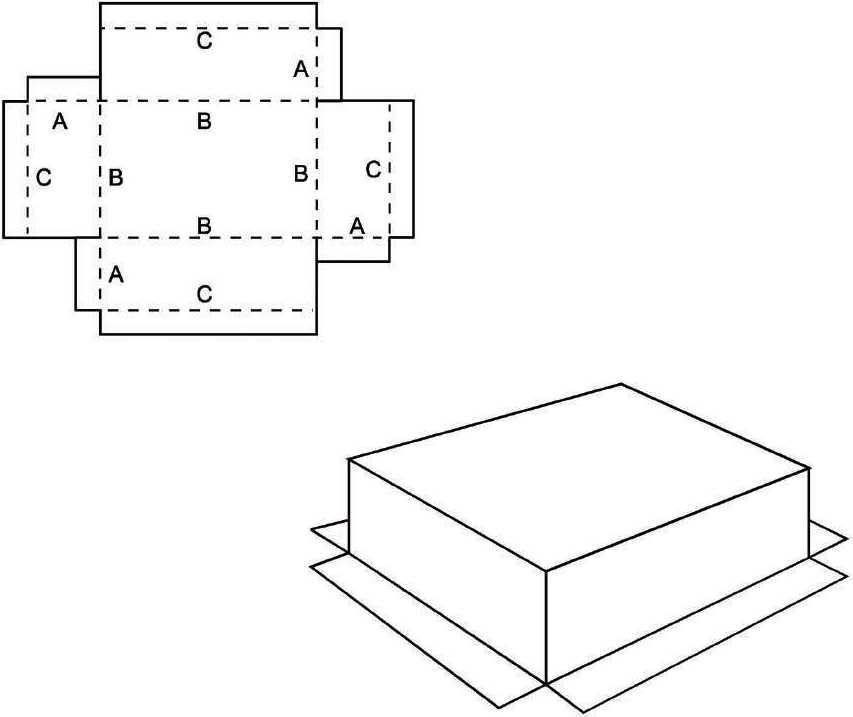

I-SLOTTED CLAMPBAR

UKWAKHA AMATHLEY (USEBENZISA I-CLAMPBAR SLOTTED)

I-Slotted Clampbar, uma ihlinzekwa, ilungele ukwenza amathreyi namapani angashoni ngokushesha nangokunembile.Ubuhle be-clampbar eboshiwe ngaphezu kwesethi yama-clampbar amafushane okwenza amathreyi ukuthi unqenqema olugobayo luqondaniswe ngokuzenzakalelayo nawo wonke umshini, futhi i-clampbar iyaziphakamisa ngokuzenzakalelayo ukuze kube lula ukufakwa noma ukukhishwa kocezu lokusebenza.Noma kunjalo, ama-clampbars amafushane angasetshenziswa ukwenza amathreyi okujula okungenamkhawulo, futhi-ke, angcono ekwenzeni izimo eziyinkimbinkimbi.

Lapho zisetshenziswa, izikhala zilingana nezikhala ezishiywe phakathi kweminwe yebhokisi elivamile kanye nomshini wokugoqa amapani.Ububanzi bezikhala bukhulu kangangokuthi noma yiziphi izikhala ezimbili zizolingana amathreyi ngaphezu kobubanzi obuyi-10 mm, futhi inombolo nezindawo zezikhala zinjalokubo bonke osayizi bethreyi, kungatholakala njalo izikhala ezimbili ezizoyilingana.(Osayizi bethreyi abafushane nabade kunawo wonke i-clampbar efakiwe izobafaka bafakwe ohlwini ngaphansi kwe-SPECIFICATIONS.)

Ukugoqa ithreyi elingashoni:

- Songa izinhlangothi ezimbili ezimelene zokuqala namathebhu ekhona usebenzisa i-clampbar eboshiwe kodwa ungaziba ubukhona bezikhala.Lezi zikhala ngeke zibe nomthelela obonakalayo kumafolda aqediwe.

- Manje khetha izikhala ezimbili ozogoqa phakathi kwazo izinhlangothi ezimbili ezisele.Lokhu empeleni kulula kakhulu futhi kuyashesha ngokumangalisayo.Vele udwebe umugqa ohlangothini lwesobunxele lwethreyi eyenziwe ngokwengxenye ne-leftmost slot futhi ubone ukuthi asikho yini isikhala sohlangothi lwesokudla ongaphushela kulo;uma kungenjalo, shelelezisa ithreyi kuze kube uhlangothi lwesokunxele lube endaweni yesikhala esilandelayo bese uzama futhi.Ngokuvamile, kuthatha cishe 4 ukuzama okunjalo ukuthola izikhala ezimbili ezifanele.

- Ekugcineni, ngonqenqema lwethreyi ngaphansi kwe-clampbar naphakathi kwezikhala ezimbili ezikhethiwe, phinda izinhlangothi ezisele.Izinhlangothi ezakhiwe ngaphambilini zingena ezindaweni ezikhethiwe njengoba ukugoqa kokugcina sekuqediwe.

Ngobude bethreyi obucishe bulingane ne-clampbar kungase kudingeke ukuthi kusetshenziswe ingxenye eyodwa ye-clampbar esikhundleni se-slot.

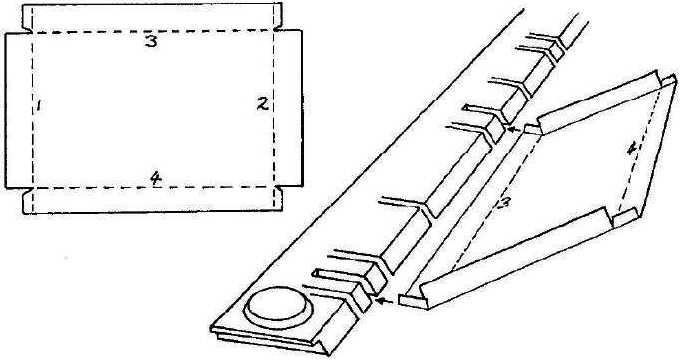

IZIMVA

UKUSEBENZISA IZINDABA

Ama-backstops awusizo lapho inani elikhulu lokugoba kufanele lenziwe konke okuyibanga elifanayo ukusuka onqenqemeni lwe-workpiece.Uma ama-backstops esethwe kahle noma iyiphi inombolo yokugoba ingenziwa ngaphandle kwesidingo sanoma yikuphi ukulinganisa noma ukumaka kucezu lokusebenza.

Ngokuvamile ama-backstops azosetshenziswa ne-bar ebekwe ngokumelene nawo ukuze kwakheke indawo ende lapho kubhekiselwa khona unqenqema lwesiqeshana sokusebenza.Ayikho ibha ekhethekile enikezwayo kodwa ucezu olunwetshiwe olusuka ogoqweni olugobayo lungasetshenziswa uma enye ibha efanelekile ingatholakali.

QAPHELA:Uma kudingekile ukusetha i-backstopngaphansii-clampbar, khona-ke lokhu kungenziwa ngokusebenzisa umugqa we-sheetmetal ubukhulu obufanayo nocezu lokusebenza, ngokuhlangana nezingemuva.

UKUNEMBA

UKUHLOLA UKUNEMBA KOMSHINI WAKHO

Zonke izindawo ezisebenzayo ze-Jdcbend zenziwa ukuthi ziqonde futhi zibe flat zibe phakathi kuka-0.2 mm kubo bonke ubude bomshini.

Izici ezibaluleke kakhulu yilezi:

- ubuqotho bendawo yokusebenza yogongolo olugobayo,

- ukuqondisa konqenqema olugoba lwe-clamp bar, futhi

- ukufana kwalezi zindawo ezimbili.

Lezi zindawo zingabhekwa ngokunemba okuqondile kodwa enye indlela enhle yokuhlola iwukuba ireferensi yendawo enye kwenye.Ukwenza lokhu:

- Swayipha i-beam egobayo iye endaweni engu-90° bese uyibamba lapho.(I-beam ingakhiywa kule ndawo ngokubeka ikhola ye-back-stop clamp ngemuva kwesilayidi se-engeli esibanjeni).

- Qaphela igebe phakathi konqenqema olugobile lwebha yokubopha kanye nendawo yokusebenza ye-beam egotshwayo.Ukusebenzisa izilungisi zebha yokubopha setha lesi sikhala sibe ngu-1 mm ekugcineni ngakunye (sebenzisa ucezu olulahliwe lweshidi lensimbi, noma igeji yokuzizwa).

Hlola ukuthi igebe liyafana yini yonke indlela ku-clampbar.Noma yikuphi ukuhluka kufanele kube phakathi kuka-±0.2 mm.I-Tliat yigebe akufanele lidlule ku-1.2 mm futhi akufanele libe ngaphansi kuka-0.8 mm.(Uma izilungisi zingafundi okufanayo ekugcineni ngakunye bese zisethe kabusha njengoba kuchazwe ngaphansi kwe-MAINTENANCE).

Amanothi:

- Ukuqonda kwe-clampbar njengoba kubonwa ekuphakameni (kusuka ngaphambili) akubalulekile njengoba lokhu kufinyezwa ngokucindezela kazibuthe ngokushesha nje lapho umshini usucushiwe.

- Igebe phakathi kwe-beam egobayo kanye nomzimba kazibuthe (njengoba kubonwa ekubukeni kwepulani ngogongolo olugobayo endaweni yalo yasekhaya) ngokuvamile liba ngu-2 kuya ku-3 mm.Lesi sikhalahhayiisici esisebenzayo somshini futhi asithinti ukunemba kokugoba.

- I-Jdcbend ingakhiqiza ukugoqa okubukhali kumageji azacile nasezintweni ezingezona ayoni njenge-aluminium nethusi.Kodwa-ke kumageji amakhulu ensimbi nensimbi engagqwali ungalindeli ukuzuza ukugoqa okubukhali (bheka imininingwane).

- Ukufana kokugoba kumageji aminyene kungathuthukiswa ngokusebenzisa izingcezu ezilahliwe ze-workpiece ukugcwalisa izingxenye ezingasetshenzisiwe ngaphansi kwe-clampbar.

AMANDENI

IZINDAWO EZISEBENZAYO

Uma izindawo zokusebenza ezingenalutho zomshini ziba nokugqwala, zingcole noma ziguge, zingalungiswa kalula.Noma yimaphi ama-burrs aphakanyisiwe kufanele afakwe ku-flush, futhi indawo engaphezulu ihlikihlwe ngephepha le-P200 emery.Ekugcineni gcoba isifutho sokuqeda ukugqwala njenge-CRC 5.56 noma i-RP7.

I-HINGE LUBICATION

Uma ifolda ye-Jdcbend sheetmetal isetshenziswa njalo, gcoba noma gcoba amahinji kanye ngenyanga.Uma umshini usetshenziswa kancane, ungase ugcotshwe kancane.

Izimbobo zokuthambisa zihlinzekwa kumalugi amabili wehinge plate enkulu, futhi indawo eneziyingi eyindilinga yebhulokhi yomkhakha kufanele futhi ifakwe okokugcoba kuyo.

ABALUNGISI

Izilungisi ekugcineni kwe-clampbar eyinhloko zilawula ukuvunyelwa kobukhulu bocezu lokusebenza phakathi komphetho ogobayo kanye nenduku egobayo.Izilungisi zisethwe njengasekuqaleni ukuze zinikeze ukujiya kwemvumo engu-1 mm lapho isilungisi sikhomba "1". Ukuze usethe kabusha lokhu, qhubeka kanje:

1.Bamba induku egobayo ku-90.

3.Ukuziba amamaki akhombisayo, lungisa izilungisi kuze kube yilapho izingcezu ze-1 mm zivele "zinqanyuliwe" kancane phakathi kwe-goba-edge kanye ne-beam egobayo.

4.Usebenzisa ukhiye we-Allen ongu-3 mm, khulula ngokucophelela i-grub-screw ukuze ukhulule indandatho eboshiwe yesinye sezilungisi.Bese uzungezisa indandatho kuze kube isisiphu senkomba sikhomba "1n.Yenza lokhu ngaphandle kokuzungezisa umzimba ongaphakathi we-ad juster.Bese uphinde uqinise i-grub-screw.

5.Setha kabusha esinye isilungisi ngendlela efanayo.

Amabhola okuphakamisa alayishwe intwasahlobo engxenyeni engaphansi yezilungisi angase anamathele uma kungena ukungcola noma umswakama obumba ukugqwala. Uma lokhu kwenzeka, lungisa ngokucindezela ibhola ulikhiphe uphinde ulikhiphe ngethuluzi elibuthuntu ngenkathi ufutha ngesigcobo esingena esifana ne-CRC. 5.56 noma RP7.

UKUDUBULA INKINGA…

Indlela elula yokulungisa izinkinga zikagesi uku-oda imojula kagesi eshintshwayo kumenzi.Lokhu kunikezwa ngokwesisekelo sokushintshana ngakho-ke kunentengo enengqondo impela.Ngaphambi kokuthumela imojuli yokushintshisana ungase uthande ukuhlola okulandelayo:

1.Umshini awusebenzi nhlobo:

a) Hlola ukuthi amandla akhona emshinini ngokubheka ukukhanya komshayeli eswishini YOKUVAKA/VUMA.

b) Uma amandla ekhona kodwa umshini usafile kodwa uzizwa ushisa kakhulu khona-ke i-thermal cut-out kungenzeka ukuthi ikhubekile.Kulokhu linda kuze kuphole umshini (cishe % ngehora) bese uzama futhi.

c) I-interlock yokuqala yezandla ezimbili idinga ukuthi inkinobho ethi START icindezelwengaphambiliisibambo siyadonswa.Uma isibambo sidonswakuqalakhona-ke umshini ngeke usebenze.Futhi kungenzeka ukuthi i-beam egobayo inyakaze (noma ishaywe) ngokwanele ukuze isebenzeni-angle microswitch" ngaphambi kokuthi inkinobho ethi START icindezelwe. Uma lokhu kwenzeka qiniseka ukuthi isibambo siphushelwe ngokugcwele emuva kuqala. Uma lokhu kuyinkinga eqhubekayo kusho ukuthi i-microswitch actuator idinga ukulungiswa (bona ngezansi).

d) Okunye okungenzeka ukuthi inkinobho ethi START ingase ibe nephutha.Uma une-Model 1250E noma enkulu, bheka ukuthi umshini ungaqalwa yini ngenye yezinkinobho zokuthi START noma i-footswitch.

e) Futhi hlola isixhumi esixhuma imojuli kagesi nekhoyili kazibuthe.

f) Uma i-clampbar ingasebenzi kodwa i-clampbar igqekezakhululakwenkinobho ethi START bese lokhu kukhombisa ukuthi i-15 microfarad (10 gF ku-650E) capacitor inephutha futhi izodinga ukushintshwa.

g) Uma umshini uphephetha ama-fuse angaphandle noma uhamba ama-circuit breaker uma ushaywe umshini, khona-ke imbangela engenzeka kakhulu ukuphephuka kwebhuloho lokulungisa izinto.

2.Lieht clamping oiwrates kodwa clamping egcwele akwenzi:

a) Hlola ukuthi i-"Angle Microswtich" icushwe ngendlela efanele yini.[Le swishi isetshenziswa ucezu lwethusi oluyisikwele olunamathiselwe ku-engeli ekhombisa indlela.Uma isibambo sidonswa ugongolo olugobile luyazungeza okunikeza ukuzungezisa ku-actuator yethusi.I-ac tuator yona isebenzisa i-microswitch ngaphakathi komhlangano kagesi. Donsela isibambo usikhiphe bese usifaka. Kufanele ukwazi ukuzwa i-microswitch ichofoza VULA futhi IVALIWE (inqobo nje uma kungekho msindo omningi wangemuva).

Uma iswishi ingachofozi okuthi VULA futhi IVALIWE shwiba i-beam egobayo phezulu ukuze i-actuator yethusi ibonakale .Zungezisa i-beam yokugoba phezulu naphansi.I-actuator kufanele ijikelezise ekuphenduleni i-beam egobayo (ize ibambelele ezitobhini zayo).Uma ingakwenzi lokho kungase kudinge amandla amaningi okubamba.Ku-1250E ukuntuleka kwamandla okubamba ngokuvamile kuhlobene nezikulufu ezimbili ze-cap-head M8 kunoma yikuphi ukuphela kwe-actuator.

UKUDUBULA INKINGA

i-shaft ayiqinile.Uma i-actuator ijikeleza

futhi ibamba KULUNGILE kodwa namanje ayichofozi i-microswitch ngakho-ke ingase idinge ukulungiswa.Ukwenza lokhu qala ukhiphe umshini endaweni yokukhipha amandla bese ukhipha iphaneli yokufinyelela kagesi.

Kumodeli 1250E indawo yokuvula ingalungiswa ngokuphendula isikulufu esidlula ku-actuator.Isikulufu kufanele silungiswe ngendlela yokuthi iswishi ichofoze lapho unqenqema olungezansi lwe-beam egobayo lunyakaze cishe ngo-4 mm.(Ku-650E naku-1000E ukulungiswa okufanayo kufinyelelwa ngokugoba ingalo ye-microswitch.)

b) Uma i-microswitch ingachofozi okuthi VULA futhi IVALIWE nakuba i-actuator isebenza kahle khona-ke iswishi ngokwayo ingase ihlanganiswe ngaphakathi futhi izodinga ukushintshwa.

c) Uma umshini wakho ufakelwe iswishi eyi-axiliary qiniseka ukuthi ishintshelwe endaweni ethi "NORMAL".(I-clamping elula kuphela ezokwazi ukutholakala uma iswishi iku-nIsikhundla se-AUX CLAMP".)

3 Clamping KULUNGILE kodwa ama-Clampbars awadedeli lapho umshini UCISHA:

Lokhu kubonisa ukwehluleka kwesekethe ye-reverse pulse demagnetising.Isizathu esingaba khona kungaba yi-6.8 Q amandla aphikisayo.Futhi hlola wonke ama-diode kanye nethuba lokunamathisela oxhumana nabo ku-relay.

4 Umshini ngeke ugobe unzima ishidi:

a) Hlola ukuthi umsebenzi ungaphakathi kwemininingwane yomshini.Ikakhulukazi qaphela ukuthi ku-1.6 mm (igeji engu-16) egoba i-ibha yokwandisakufanele ifakwe kugongolo olugobayo nokuthi ububanzi bezindebe obuncane bukhona30 mm.Lokhu kusho ukuthi okungenani u-30 mm wezinto kufanele ziphume onqenqemeni olugobile lwe-clampbar.(Lokhu kusebenza kukho kokubili i-aluminium nensimbi.)

Isikhathi sokuthumela: Oct-11-2022